I spoke to a friend that is a Colt Collector, and according to him it is pretty well common knowledge that Colt hammers were “knurled”. And are commonly called as such by collectors. Now he didn’t know as too how the process exactly worked. But went on to state that Colt collectors even know when the certain pattern knurling were used. He sent me the following.

1st Generation SAA Hammers

Left: Longest 1873 – shortest knurling ~ 1904, both with a line below it. Half Moon knurling 1905 ~ 1908. Right: knurling without borders ~ 1908 to 1940

If Colt knurled their hammers, Why wouldn’t have Winchester done the same?

clarence said

jwm94 said

…after 100,000 was passed, (about 1872), the hammers have a finely knurled pattern which was forged into the hammer.If the hammers were forged, rather than milled, that would certainly be the fastest & cheapest method of producing a checkering pattern, especially a complicated one like the Widow’s Peak. But if so, the pattern thus produced shouldn’t be called knurling, which is a machine tool operation.

Anyone, by the way, who’s seen one of those step-by-step displays of a forging operation, such as the one on exhibit at Springfield Armory Museum, should not be surprised that it could be done this way. Starting with a lump of steel, the most complicated shapes can be produced merely by repeated hammering of the hot metal in a succession of slightly different dies.

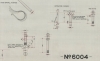

I came across this Model 1885 Design Drawing on BBHC website.

The drawing shows a note for the Hammer and Trigger “Punched and Flattened”.

The drawing shows a note for the Hammer and Trigger “Punched and Flattened”.

But the drawing also notes “Extractor-Forged”. Another neat note is a screw head with the note “Slot Large enough to take in a quarter of a dollar”.

But the drawing also notes “Extractor-Forged”. Another neat note is a screw head with the note “Slot Large enough to take in a quarter of a dollar”.

Here is the website link: http://library.centerofthewest.org/cdm/singleitem/collection/WRAC/id/8324/rec/159

So I imagine the manufacturing process of the various parts differed depending on the part in question, and the process used likely changed over the years. Again its a shame majority of the original Winchester manufacturing drawings are now lost and/or destroyed.

Sincerely,

Maverick

![]()

WACA #8783 - Checkout my Reloading Tool Survey!

https://winchestercollector.org/forum/winchester-research-surveys/winchester-reloading-tool-survey/

Maverick said

If Colt knurled their hammers, Why wouldn’t have Winchester done the same?

You provided a partial answer to this question yourself: “So I imagine the manufacturing process of the various parts differed depending on the part in question, and the process used likely changed over the years.” Different factories may use the same manufacturing system…or they may not. Furthermore, it hasn’t even been proven how Colt checkered hammers.

I’ve just spent, or rather wasted, time going through several gunsmithing books looking for descriptions of the knurling operation, when I should have gone straight to the best “how to” source of all: You Tube! Who’d have guessed that, judging from the multitude of knurling videos on YT, how popular this subject apparently is! Here’s a typical example, but there are many others:

Watch some of them, and then ask yourself how, using the tools & procedures described, the “peak” could have been created using knurling tools? And what’s more, done quickly & efficiently for mass production.

I watched a lot of YouTube videos too, but none of them showed how to knurl something with a flat and curved surface like the spur of a hammer. I also learned that some cut knurling will remove a small amount of material. I am not saying cut knurling was used only that it is another process. I did see some flat plate knurling too. Hammers are still being made so someone knows.

I watched this video. The one thing I caught that was of interest is he mentioned, and you could see, was a small amount of material was being removed.

At times like this, I wish we still had Phil 25-20 and his machinist knowledge available to us. Phil had about fifty years in this business, to include, having owned a successful enterprise as well. He is the one that after a great deal of study determined that my 45-70 WK was a factory test gun and, perhaps, one of several in this caliber, instead of what most other experts believed to have been an after market gunsmith’s efforts. His conclusion is the only one that passed on this issue as I had later come to believe that it was a special order rifle due in part to the caliber and upgraded buttstock, and he was able to shed some intelligence on the stock issue as well.

On the subject of youtube and knurling, I had checked one or two vids out the other day, myself, after one of Maverick’s informative posts and was left wondering how such a process could have been used on such a curvature, especially that of the Widow’s peak as Clarence has mentioned.

On the subject in general terms, it looks to me that Schwing, Madis, and Maxwell, give us information that compliments one another in terms involving hand and machine tools that also involve stamping and the resulting irregular patterns that improved dramatically with time.

Here’s a picture of two W-K hammers that would have been machined stamped according to Maxwell…which would better fit Whitney’s production aims where foreign market contracts were concerned. Note that the upper border where the tip of the hammer is curved is not that well defined, which appears to support Maxwell’s statement:

clarence said

Watch some of them, and then ask yourself how, using the tools & procedures described, the “peak” could have been created using knurling tools? And what’s more, done quickly & efficiently for mass production.

I think using a custom patterned knurl, like the one pictured. Along with it being a Convex Knurl, one could achieve the knurling pattern on the hammer with a Peak.

I think using a custom patterned knurl, like the one pictured. Along with it being a Convex Knurl, one could achieve the knurling pattern on the hammer with a Peak.

I also think they could of used a single knurl and not a double knurl as shown in the YouTube Video. They also could have used a “hand knurling tool” and not necessarily needed a lathe or rotating piece of equipment, if the metal was cut / knurled before being case hardened. As far as what would be more quickly and efficiently for mass production? I believe it would be much faster and efficient than have an engraver(s) cutting hammers all day long. For all I know, they may of had some type of Jig that held 10 or 50 or 100 hammers, and they knurled them all at once or in one simple procedure.

I also think they could of used a single knurl and not a double knurl as shown in the YouTube Video. They also could have used a “hand knurling tool” and not necessarily needed a lathe or rotating piece of equipment, if the metal was cut / knurled before being case hardened. As far as what would be more quickly and efficiently for mass production? I believe it would be much faster and efficient than have an engraver(s) cutting hammers all day long. For all I know, they may of had some type of Jig that held 10 or 50 or 100 hammers, and they knurled them all at once or in one simple procedure.

Sincerely,

Maverick

![]()

WACA #8783 - Checkout my Reloading Tool Survey!

https://winchestercollector.org/forum/winchester-research-surveys/winchester-reloading-tool-survey/

Maverick said

As far as what would be more quickly and efficiently for mass production? I believe it would be much faster and efficient than have an engraver(s) cutting hammers all day long.

Never meant to suggest engraving; the faster alternative would be stamping or forging (if the hammer was forged rather than machined).

Even using a knurling tool with a complex pattern such as the one in the illustration, wouldn’t it still have to be applied with a rotating action? The essence of knurling, regardless of how many tools are employed, appears to me to be rotating the tool against the part to be knurled–as opposed to the simple up & down action of stamping (and I don’t mean hand-stamping!). The set-up required to hold the hammer & the tool in the proper orientation to allow such a rotary motion seems to me a good bit more complicated than a simple stamping operation, not that it couldn’t be done, but that it might be more time consuming; and time is money in any sort of manufacturing operation.

Bert H. said

For the Model 1894, the “widow’s peak” hammer was used from the beginning of production through early 1903. Through the information in my research survey, the transition from the Type-1 (widow’s peak) to the Type-2 hammer took place in March/April 1903. I suspect the same is true for the Model 1892.

Bert

In fact… The widow’s peak hammer style starts being replaced in late 1895, is mixed in 1986, and is last seen in very early 1897. That is a full 6 years prior to the change in the Model 1894!

Michael

Model 1892 / Model 61 Collector, Research, Valuation

Bert H. said

Chuck,To the best of my knowledge, all of the early Winchester models (rifles & carbines) have the widow’s peak style hammer. The Type-2 hammer has the same style checking (or knurling), but without the pointed peak. The Type-2 hammer was used from 1903 through early 1946, when it was replaced by the Type-3 Serrated hammer.

Bert

And it is more complicated on the Model 1892 rifles. When the widows peak hammer was replaced the style is the same but without the peak but retains the bottom rounded border. Then… the border goes out of use but the bottom stays rounded until the bottom of the knurling is square. Was somebody expecting a clear simple answer to all of this?

Rounded Bordered

Rounded Unbordered

Square Base

Michael

Model 1892 / Model 61 Collector, Research, Valuation

Chuck said

Chris, thank you for the pictures. I really didn’t want to dig out my guns. It is my opinion that your pictures show so many inconsistencies that I believe they were hand cut.

My interpretation is that over a period of time that the “stamp” used to knurl the pattern is worn out and new ones have to be “hand cut” so that production can continue. The variation is therefore a factor of the various stamps being slightly different and the wear which occurred over that stamps useful life.

Chris, are those 1892 or 1894 hammers?

Michael

Model 1892 / Model 61 Collector, Research, Valuation

twobit said

My interpretation is that over a period of time that the “stamp” used to knurl the pattern is worn out and new ones have to be “hand cut” so that production can continue.

Of course! Like every roll die or hand-stamp. (No laser cutting machines to put engravers out of work!)

But if THAT is what Schwing meant by saying they were “hand engraved,” one short sentence such as you just wrote would have made his meaning crystal clear. (And reduced the length of this thread by several pages.)

Here is another point to take into account. I took the year 1897 and totaled up the production of just the Model 1892. 1894 and 1890 rifles. There were 41,001 combines rifles for these three models alone. That would require A LOT of man hours of hand engraving to produce that many hammers and there were still MANY other firearms requiring them. I can not fathom how having these individually done by hand would make any economic sense for Winchester.

Michael

Model 1892 / Model 61 Collector, Research, Valuation

WACA Life Member--- NRA Life Member---- Cody Firearms member since 1991 Researching the Winchester 1873's

Email: [email protected]

1873man said

Micheal,Stamps that were made by a engraver sometimes were identified by them so if the stamp needed repair, it was returned to him, annealled and repaired. Here is a example of one.

Bob

Where did you obtain that? Any ideas where to find ones from Winchester, Colt, Smith & Wesson, or other 19th C manufacturer? I would like to collect several for display purposes.

Any idea as to how to value such stamps or dies?

I bought a collection of 73 gauges and tools from another collector and it had several stamps in with them. At the Tulsa show I picked a few more tools and gauges. I have some stuff for the 95 and other models. Some of the tools were used for multiple models if the part was interchangeable. Hear are a couple more stamps I have for marking the caliber on the elevator. These also have the Ulrich stamp on them

Bob

WACA Life Member--- NRA Life Member---- Cody Firearms member since 1991 Researching the Winchester 1873's

Email: [email protected]

Michael, Those are 1894 hammers. I may be able to get more pics of other 1894 hammers over the weekend just to post to compare different variations if present and expand on the pics for folks to see, and the more examples you have the more you have to compare.

I did notice on a couple of the ones that I already posted there were some commonalities between the checking pattern that you would not expect to find if they were hand cut. If you look at the width, depth, and thickness of some of the lines or in a couple examples at the top left corner of the checking there is a small sliver of metal that does not have a check line going through it among others commonalities.

twobit said

Chris, are those 1892 or 1894 hammers?

1892takedown @sbcglobal.net ......NRA Endowment Life Member.....WACA Member

"God is great.....beer is good.....and people are crazy"... Billy Currington

The following excerpt was taken from Discover Eli Whitney:

http://teachersinstitute.yale.edu/curriculum/units/1979/3/79.03.03.x.html

In 1799, as Whitney worked in New Haven, Simeon North was making 500 pistols for the government by using machines and a division of labor just 20 miles away in Middletown. The parts were so well made that little or no filing was needed at time of final assembly. His son, Selah, invented a filing jig—matching concave molds that held the piece that forced the men to follow the contours of the jig in filling the piece to be shaped. Edwin Battison, in his article, “A New Look at the ‘Whitney’ Milling Machine”, argues that the milling machine, which is a power tool used for cutting and grinding metal parts, originated with Simeon North. Interchangeability requires precision machine tools to make exact parts; it appears that the Whitneyville milling machine was made after Whitney’s death when his nephews modernized the factory in 1827.

The note about the “filing jig” plus the one from Madis about the checkering being accomplished by a milling operation, which brings to mind Schwing’s comment about the possibility that two different craftsmen using different tools with, perhaps, one operating the milling machines to cut and grind the metal, and the other operating filing jigs for a better finished product, which might also explain, if true, why the early hammers were crude when compared to those made at a later date by better machinery up to 70+ years later.

It would nice if some machinists would weigh in on this subject!

James

1892takedown @sbcglobal.net ......NRA Endowment Life Member.....WACA Member

"God is great.....beer is good.....and people are crazy"... Billy Currington

Quick question concerning model 1892 hammers. Any idea when Winchester switched from color case hardened hammers to blued for the model 1892? Reason being, I just bought a model 1892 carbine, serial number 287849, it has a case colored lever, but blued hammer. The hammer is square based as in Michael’s picture above. Michael has this particular carbine in his survey.

Thanks,

Al

Hello Al,

In my survey I am trying to determine when the change from CC to blued for the hammer and levers. The problem is that these parts are typical so worn that it is hard (read impossible) to tell what they were without hands on inspection and I am only working with peoples poor photos most of the time. It is my belief (no documented proof) that the change happened at the same time for both parts. The best I have determined is it was around 1915. I will eventually be going back into the photos I have of each rifle in the survey and try to take a second look to narrow it down. Can you send me a photo of the hammer on that wonderful carbine of yours please?

Michael

Model 1892 / Model 61 Collector, Research, Valuation

1 Guest(s)

Log In

Log In Members

Members Home

Home

Add Reply

Add Reply Add Topic

Add Topic

Offline

Offline