Let the spending begin.

Got a Redding Type S full length bushing die for Christmas

Also got a Short Action Customs 270 bullet comparator and a case comparator

Bought or ordered:

Forester micrometer bullet seating die

Whidden .300″ neck bushing

21st Century .275″ neck mandrel

50 ea. 270 Win Norma cases

Berger VLD, Sierra Match King and Hornady ELD-X bullets

A 270 Win 3 way cutter head for the Giraud case trimmer

MTM Case Gard ammo box

Hornady die side lock rings

Brownells 270 rifle cleaning jag

Iosso and Brownells nylon cleaning brushes

Already had:

H-4831 SC powder

Federal Premium 210 match large rifle primers

#3 shell holder

Front rest or bipod

Rear bag

The next and most expensive purchase will be a scope, the bases and rings. Not sure what I want or if I can use one of my existing scopes. I want enough power to actually see where I am aiming at 100 yds. So power will be about twice that of my hunting scopes. The objective lens diameter will determine the base height needed to clear the barrel.

I have not even looked down the barrel with my bore scope so it will be what it will be.

Loading:

I have primed the brass to .008″ below flush. I wanted to run a primer pocket uniformer first but the pockets were too tight to get the cutter in them. I may reduce the diameter of the cutter. I don’t have a flash hole deburring tool for this caliber.

All I have done to the cases was to run the .275″ expander mandrel in them. This will produce .002″ to .004″ of neck tension. The Norma brass wall thickness varies this much. I may have to use different bushings or mandrels. I really don’t want to neck turn the brass.

I set the primers at .008″ below flush because world class shooters have tested seating depths and have found that this is a good depth. The main thing to remember is, at a minimum, you should seat the primers so the cup is bottomed out. This assures that the anvils are all touching the bottom of the pocket. I have a gauge that measures primer pocket depth, primer thickness and final seating depth. The seating tool I use can be adjusted .001″ at a time.

My next thing is I’m going to find hard jam on the bullets by seating them long and forcing them into the case by closing the bolt. When doing this you have to have your neck tension already figured out. Hard jam is not where you want to seat and shoot your bullets. Some world class shooters seat their bullets at hard jam minus .020″. I’ve tested this method and it does not pose a pressure issue but didn’t give me the best results.

After finding hard jam I usually start seating the bullet into the case to the point my stripped bolt will just drop on it’s own. This is touch. But, I’m not sure if the controlled feed on the Mod 70 bolt will do this? I need to pull the firing pin and see. If not I will take a fired case and tap and thread the base and use the Hornady Lock n Load tool to find the lands. So somewhere less than hard jam the barrel will tell me what seating depth is best.

After I test the bullets for touch I will use a powder charge that is safe and a bullet seating depth that will keep the case tight against the bolt face so I can fire form the cases. When fire forming you are only concerned about getting the shoulder to lengthen to the point it touches the inside of the chamber. It make take several firings. If not done properly your cases may stretch at the base and then can lead to case head separation down the road.

After fire forming the real load development can start.

I know many will think what I’m going to do is overkill for hunting purposes but everything adds up and your ES/SD and group size will improve. How much we will have to wait and see.

November 5, 2014

Offline

OfflineHi Chuck-

Please keep this thread going as you progress…

One the one hand, prior to my last big game (elk) hunt in 2009, I had never used anything but hand loaded ammunition in my centerfire rifles and handguns… On the other, I was never as systematic a reloader as you are. Somewhere in-between-ish maybe… 😀

Found some loads my guns “liked” but I’m sure I could have done better had I taken the time to do it right!!!

Best,

Lou

WACA 9519; Studying Pre-64 Model 70 Winchesters

![]()

Thanks Lou for the encouragement. I am going to post my progress as I did for the Lee Navy.

One problem I have encountered is the safety is stuck in the fire position. I keep messing with it and got it centered a couple of times. I took the firing pin assembly out and cleaned it. The fire control system on the target guns get a lot of work done so nothing impedes the forward progress of the firing pin. Areas get clearanced, polished and springs are chamfered and deburred. Springs get changed on a regular basis and the amount of firing pin fall is checked.

Last night I took a Hornday 145 gr. ELD-X bullet and jammed it into 5 cases to find hard jam. Base to ogive of the round ranged from 2.691″ to 2.694″. The difference is due to the inconsistency of the neck thickness causing different neck tensions. I’m going to use 2.691″ as my starting point. When fire forming I will use something less that 2.671″. At this point I know I’m in the lands but don’t know how much. I need a fire formed case to tap and thread for the OAL gauge. With this I can find touch. You need a case that the shoulder is touching the inside of the chamber to be accurate. If not all your headspace measurements will be off.

November 7, 2015

Offline

OfflineSounds like fun, some new techniques I haven’t read about. Is there an advantage to a purpose built flash hole deburring tool? I use one with an adjustable (for length) collet and a few wraps of tape to increase the diameter. I’m switching over to Hornady cases when I can, one benefit is no flash hole burr. I have a few surplus hunting scopes around but probably nothing over 10X.

Mike

I mainly use Lapua brass when it counts. Lapua supplies a lot of brass for the war effort so they aren’t making 270 right now. 30-06 brass could be used but it is too short for what I want to do. The necks end up shorter which limits the seating depth range. With Lapua you don’t have to worry about the primer pockets, flash holes and neck thickness. The type of deburring tool I like is caliber specific and it won’t cut too deep. The cheaper ones often keep cutting as you add more pressure. Flash hole deburring is not something you have to do most of the time but I have never checked Norma brass.

Today after my weekly visit to the gun shop I had some time to mess with the rifle. I played with the stuck safety and got it to open a couple times. Sprayed it with more Kroil.

I ran a patch down the barrel and it came out dirty. Then ran a few patches with alcohol until they cleaned up a bit. I took out my bore scope and shot these pictures. The first one is at the junction of the free bore and the rifling. This is an area that can build up a ring of hard carbon and copper. The next 3 are going further down the barrel. I am now soaking the barrel with cleaning solvent.

I looked at 3 of my loading manuals for a starting charge for H 4831 SC. I’m going to start with 56.5 grains. This is about 3/4 of the way up before the max.

I let the barrel soak over night then ran a wet patch. I then took a .308″ nylon brush and ran it back and forth 10 times. ( I don’t have a 270 jag or brushes yet) I am using a 6.5 jag and 308 patches. I cut a small strip off one of the patches as a backer to make the 308 patch a little tighter. I then patched it out and took some pictures. Image 5 is at the start of the rifling. 6 is going down the barrel and is consistent for the first 12″. But after that there is still some copper. See pic 7. Ran a wet patch and will let it soak over night again.

If you don’t have a bore scope buy a Teslong. It will teach you that a clean patch does not mean you have a clean barrel. And a lot more. You’d be surprised where you can stick one of these.

https://teslong.com/products/new-rifle-borescope-with-4-5-inch-ips-hd-screen I have the 26″ rigid but the 45″ flexible may be your choice. It comes with 5 mirrors.

Chuck, Note the tool marks, especially the last picture where the copper is beginning to come off and highlights the tool marks on top of the land. Actually its aa pretty good production barrel. Custom barrels that were lapped show why they are custom. But that does not make them more or less accurate as one rifle brand has bores rough as a cob yet shoot well. What it does mean is how easily it cleans up. Tim

Yesterday I loaded 51 cases with H 4831-SC. The container said 59.5, Hornady manual said 59.9 for max, Sierra manual said 56.2 for max and the Berger manual said 55.7 for max. Most of these were assuming a 150 gr bullet. I’m using a 145 gr Hornady so the Hornady info is for this bullet.

So which is correct? In my experience, none of them. I picked 56.5 grains. Well under what Hornady says is max. My scale can weigh to .02 grains of accuracy. That means my loads are 1 kernal apart, max. Most manuals use safe numbers. I read an article years ago about how several manufacturers selected the MAX. I can’t remember the exact details but none of them want to get sued. I will find my Max during the powder ladder testing.

I seated the one odd ball case at the longest hard jam number I got. 2.694″ base to ogive. The rest are seated at 2.671″. This is minus .020″ from the shortest hard jam I got. All of these are over the COAL. COAL is only used for fit in a magazine. These are in the lands but I don’t know how much. I want the round to be up against the bolt face and the bullet in the lands. This way the case will stretch where it should. Too much headspace will cause the case to stretch at the .200″ line and possible cause case head separation down the line. I want this brass to last as long as possible.

The first 5 rounds and the odd ball may have different fps because these had bullets inserted and then removed. The brass rebound enough to hold the bullets. I haven’t received my neck bushing yet to reset the tension. So the neck tension will be less. I’ll shoot the first 5 first to get the barrel up to temp and foul the barrel. I will shoot the odd ball next. This case will be the one I drill and thread to check for bullet touch. Remember, I’m just trying to fire form these cases. I will shoot at a target and chronograph each shot. If I can. Supposed to be very windy and it may blow over the chrono or blow away the target.

I was able to shoot the 51 rounds today. But the wind crashed my chrono and ruined the cable to the battery. So I did not get any fps readings.

The round that was loaded with the bullet at the longest hard jam setting did cause some extra lift for the bolt. Definite pressure sign.

The other 50 rounds that were seated .020″ deeper into the cases shot normal. None of the 51 primers looked bad.

I measured 26 cases, base to shoulder. Measured 1.905″ or 1.906″. All of them grew between .004″ to .006″. 2/3 grew .004″. If I were to use these numbers I would use the 1.906″ and size them to 1.904″. I will shoot all of these 1 more time. I will only neck size them. I finally got the .300″ neck bushing so the neck tension will be more consistent. I will make no other changes and will shoot the hot one too so I can get the fps. Mother nature willing.

Barrel is soaking. I cleaned it 4 times and did not get all of the copper out and ran out of time. I will clean it every day this week if I have to.

David, this will be a long term project. I’m hoping it will end up well. But, no promises. I have little control over the quality of this barrel. Reminds me I have cases to prep.

I’m not sure if the range will be open Tuesday because of the fires. This canyon is not far from one of the larger fires. It only has one way in or out. The range and buildings were burnt out some years ago and re construction is still going on. Right now they are building a new and extra water storage tank. There is an old fire truck on site at all times. Several small fires were put out in the last couple years. The office is a couple of trailers because the original block building has not been re built.

Myself and my family are not in harms way. But thank you. I live about 15 to 20 miles south of the mountains. The wind can cause fires here too but usually the worst ones are near the mountains or foothills. By the time the wind comes out of the mountain passes and hits the flat open ground it calms down a bunch. Like 90 mph to 30 mph.

Still soaking the barrel.

Uniformed the primer pockets and got out a lot of brass. Now each one is the same depth. From now on I will use the uniforming tool to clean the pockets. Neck sized the cases. Now that I have the .300″ bushing the necks should have come out at .300″ OD but instead they are .298″? I then ran the .275″ mandrel in them. I measured 10 pieces of brass. 6 are .301″ OD and the other 4 are .300″. After I seat the bullets I will measure them again. The difference is the neck tension. I cleaned the brass and will chamfer and de burr the case mouths.

It’s time for me to talk about some of the tools I use.

Presses

The red ones are Forester Co Ax. These are very accurate, have a lot of power and the dies load from the front. Dies and case float.

Scale

This is the A&D FX 120 and is accurate to .02 grains. Notice there are 5 kernals in the pan.

Calipers

The top one is set up to measure the base to ogive of the bullet when seating bullets.

The bottom one is for measuring the base to the shoulder for setting head space.

The 2 shinny pieces below the calipers are a bullet caliper that is sized to the lands of the barrel and a case caliper that is sized for the exact shoulder angle of the case.

More tools.

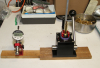

Tool with a fire formed case attached for finding where the bullet touches the lands.

Type S bushing die and micrometer seating die. Notice the expander mandrel and the bushing. The mandrel goes in a different die. The center shaft of the die has the de capping pin removed and the expander button.

Tool for loading primers into the tubes.

Primer seating tool and the gauge that measures the seating depth. Seater has .001″ adjustments. The gauge can measure primer pocket depth and primer thickness too.

1 Guest(s)

Log In

Log In Members

Members Home

Home

Add Reply

Add Reply Add Topic

Add Topic