Anyone have a friction lock for the mag tube on a 1906? Let me know how much to send. I need it fast, before the end on this month.

Vince

Southern Oregon

NRA member

Fraternal Order of Eagles

“There is but one answer to be made to the dynamite bomb and that can best be made by the Winchester rifle.”

Teddy Roosevelt

Vince,

I don’t have an extra or it would be yours. If you cannot find one I have been successful in replicating them in the past using a small piece of hacksaw blade. First anneal the blade, then grind the shape while keeping it cool. Use a small file to form the 90 degree inside corners. Once you get the proper shape and put the slight re-curve bend in it you can then re-harden/quench it and then temper it. I simply temper them by color and draw them to a medium blue (about 575 deg.) before re-quenching in oil.

The whole process can be completed in 20 minutes and only requires a small grinder, small file, a propane torch, pliers and a container with some oil for quenching.

I have also heard you can cut/grind one from a pen/mechanical pencil pocket clip but most of those are chromed and I have no idea if it is spring steel or not so I have never tried it.

Hopefully someone has a spare to save you the work though.

Safe travels and Best Regards,

WACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

I would make one but I need to know the correct dimensions. I’ll give it a week then try to come up with a custom handmade edition.

Vince

Southern Oregon

NRA member

Fraternal Order of Eagles

“There is but one answer to be made to the dynamite bomb and that can best be made by the Winchester rifle.”

Teddy Roosevelt

Vince said

I would make one but I need to know the correct dimensions. I’ll give it a week then try to come up with a custom handmade edition.

I wrote them down the last time I made one. Give me a few minutes and I will dig them out and shoot a few pictures of an original for you.

Best Regards,

WACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

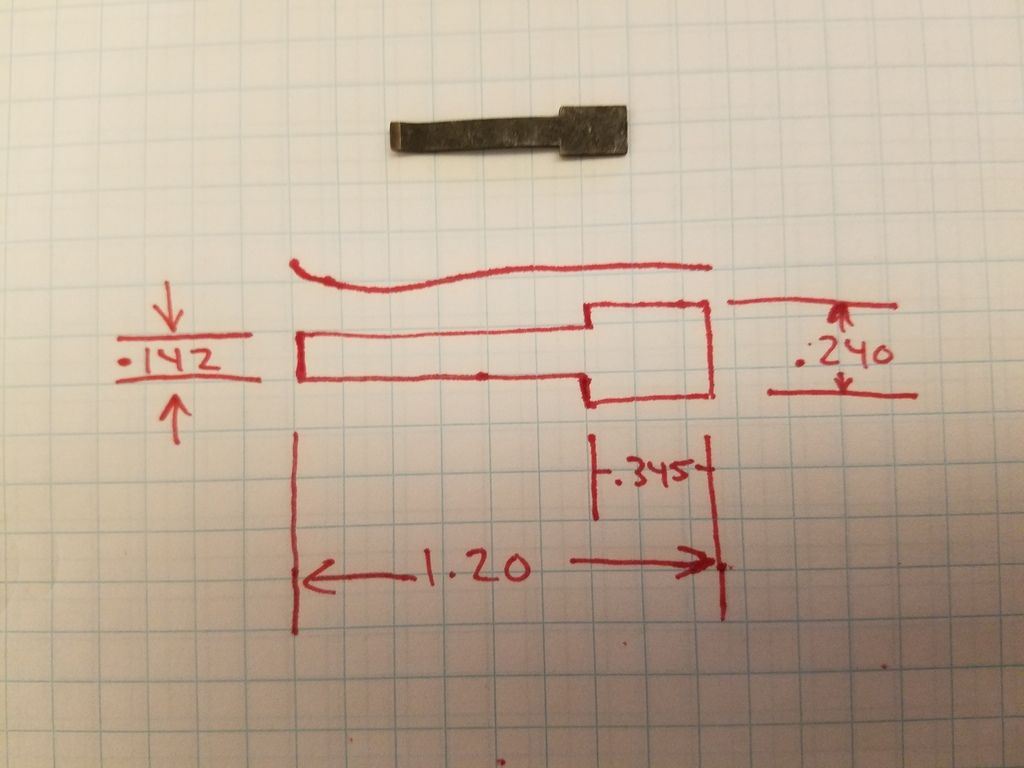

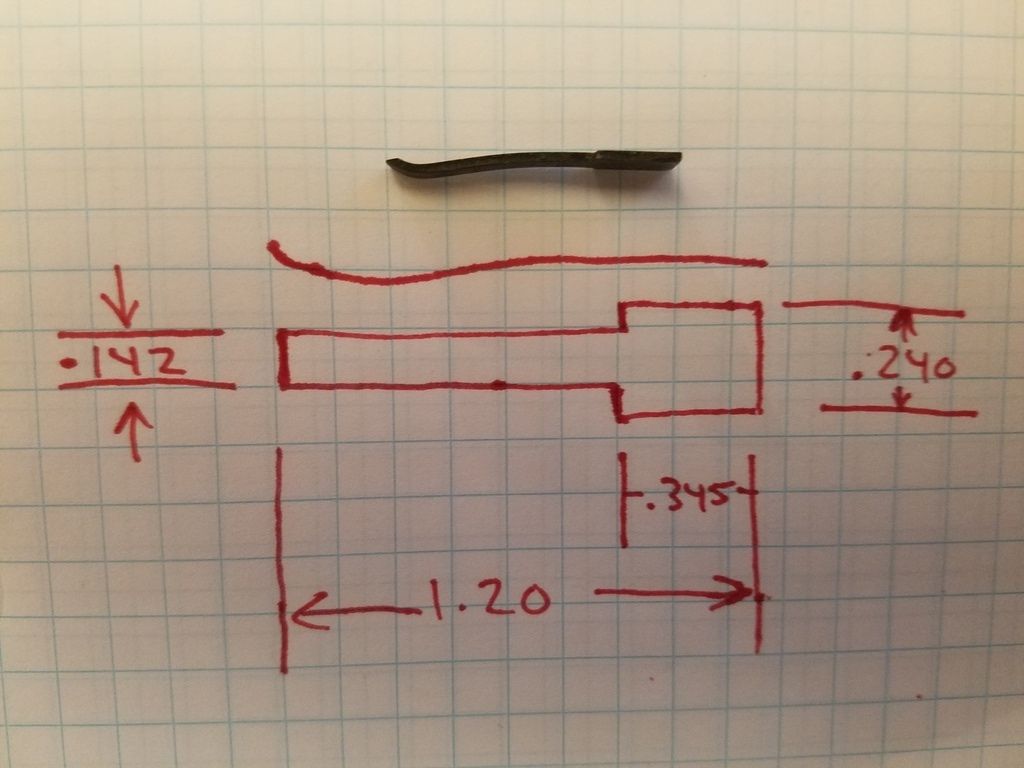

Here are the dimensions and an original tension spring I pulled off of a rifle. The original material thickness is .042″ but that is not a critical dimension as the hack saw blade is slightly thinner. Also, The sketch dimensions are in inches and all angles are 90 deg. Adjust the re-curve to apply the amount of tension you want against the inner magazine tube (just like the originals). There is a small flat on the tip of the small end of the spring. I use a whetstone to form that flat after everything else is done but you can also do it with a grinder or emery paper on a flat surface. Just make sure it is smooth with no sharp edges to gouge the inner magazine tube. You want the tube to glide along the spring.

It is VERY simple to make one, it sounds much more complicated than it really is.

Best Regards,

.

WACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

Thanks! Now I know what I’ll be doing in the next day or two. Let’s see, 1.2 inch….where is the tenths on this damn ruler? ?

Vince

Southern Oregon

NRA member

Fraternal Order of Eagles

“There is but one answer to be made to the dynamite bomb and that can best be made by the Winchester rifle.”

Teddy Roosevelt

1 Guest(s)

Log In

Log In Members

Members Home

Home

Add Reply

Add Reply Add Topic

Add Topic Offline

Offline