March 12, 2023

Offline

OfflineHello everyone, this is my first post and I’m happy to have found this community! I went to my local gun pusher to browse a few days ago and ended up buying a model 70 pre-war. I am not an expert on these, so if someone could chime in with some wisdom I would much appreciate it.

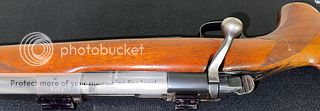

This rifle has the good/bad/and ugly dynamic going on and I have the feeling i was taken to the cleaners, but it is certainly an early example. The serial number is 3161. It is a 22 Hornet, with Kilbourn stamped right above the caliber marking. Polishing room records indicate a 1936 manufacture date. It has an old sears scope mounted on it. Ill upload some pictures of it later.

Did Winchester ever produce the K-Hornet or was this certainly re-chambered? At first I was excited, thinking this could be one of the first K-Hornets, but after thinking about it, who knows who did it or when.

The serial number on the bolt is kind of strange. Does this specific area of the bolt get beat up with use? Most of the bolt is smooth like a jewel, but that part is not, so either it is a high wear area or someone ground out the original serial number maybe? the “1”s on the bolt are slamted like “7”s, so it almost looks like 3767.

The ugly- the stock was broken off behind the receiver but repaired pretty well. I think the bolt handle was ground to clear the scope. Again they did a good job of it but I need to see a picture of a factory handle to see.

Would it hurt to remove the action on this to clean and inspect it? Would it mess up the bedding?

I think the blueing looks good for its age and need to look closer to make sure it was not re-blued. There are a few nicks in the barrel and they went through the blueing, the scope had years of dust on the lens, so I’m thinking this was just an honest old user. Screw slots show they have been used, they are not gummed up bad but they probably removed the stock to repair it. Bore looks decent. If it shoots good then maybe paying 2k for it to just enjoy owning and shooting an old model 70 will be worth it.

March 2, 2023

Offline

OfflineWithout pictures, hard to really give an honest assessment of the gun and bolt. It appears to be somewhat conflicting in terms of when they started making them. It says dates of manufacturing started in 1936, but they weren’t cataloged until 1937. 1937 was the first year the 22 Hornet was cataloged, so I think it’s probably safe to say it wasn’t re-chambered and it was one of the original 22 hornets made (Guns cataloged in 1937 had serial numbers ranging from 2239-11573).

22 Hornet was kind of middle of the pack relative to chamberings offered over the life of the pre-64. 20,306 manufactured in total between 1936 and 54, which represented 3.5% of the total production.

Can’t say the 22 Hornet has been on my wish list of pre-64’s, so I’m not super up to date on the value. I would suspect given some of the noted condition issues and alterations, you may have overpaid for it but probably not egregiously. If you like it and it shoots well, I wouldn’t get too hung up on it.

Bob

March 12, 2008

Offline

OfflineYour Hornet was serial numbered in December of 1936. It would have been assembled and sold most likely sometime early in 1937. Winchester did not chamber any 70’s for the K Hornet. This has been done after it left Winchester and was a relatively common occurrence. Most gunsmiths would simply hand stamp “K” or “Kilbourn” on the barrel to show that it has been rechambered. Many times they didn’t bother to stamp barrel, that is why I always carry a K-Hornet case with me to the gun shows. You will certainly not hurt the value of the rifle removing the stock. While you have it off, check on the bottom side of the barrel just in front of the receiver for a 2 digit date stamp. I would bet it is probably stamped “37” which designates the year the barrel was manufactured. This is all assuming it still has the original Model 70 on it. It is a great little cartridge and has a bit more poop than the original Hornet. With the modification and broken stock it will never have a significant collector value so enjoy it for what it is, a great little shooter. Also, you mention the bolt handle being ground, if it had a scope, the rear bridge of the receiver is most likely drilled/tapped for a scope base which was not factory either. Pictures would be great.

Steve

March 12, 2023

Offline

OfflineThanks Bob and Steve, great posts. I’m going to try to upload pictures tonight. After cleaning the bore and looking closer I am feeling better about it. I think the bluing is original and the bore honestly looks great as far as my eyes can tell. Everything seems solid, but like Steve mentioned it does have a broken stock, drilled and tapped receiver, and The bolt has that oddity. Reading up on the K-hornet, I’m kind of getting excited to shoot it and fireform some cases! Anyone know where I can get a rear sight for the dovetail?

March 12, 2023

Offline

Offlineclarence said

Marcus Tillius said Anyone know where I can get a rear sight for the dovetail?

Not hard to find on ebay (#22G), but why not use the Sears scope that came with it? (Good chance it’s a Weaver.) Given its condition, more money spent on it would be unrecoverable.

Good Point. Its a Ted Williams 3×9 by Sears. The glass cleaned up beautifully! I will probably leave the mounts on the rifle and give that a try first.

March 12, 2008

Offline

OfflineI see it still has the correct flat early magazine release button as opposed to the later angled version. Also, the trigger does not look original. Possible an aftermarket. It would be great to see a picture of the bottom of barrel stampings and a good close up of trigger assy while out of the stock.

Steve

November 5, 2014

Offline

OfflineSteve-

Correct me if I’m wrong but is seems to me that the underside of the bolt body beneath the anti-bind lug, right where the S/N is usually inscribed, is commonly “roughed up”, especially in pre-war guns. Often looks like it was ground on by hand with some sort of rotary grinder. I don’t know if this had something to do with fitting the bolt to the action rails for slick operation, or what, but it seems commonplace.

Pics below are of the underside of the bolt on S/N 4796, a type I-1 220 SWIFT Standard Rifle. Early 1937 gun pretty close to the OP’s rifle. I’m pretty sure this one does not have a replaced bolt. If it does than about half of my pre-war M70s have replaced bolts since many of them look pretty much like this…

I totally agree that the trigger on Marcus’ gun has been altered or replaced. If the sear engagement surface on the striker hasn’t been altered it should be easy/cheap enough to find a replacement factory trigger/sear if desired…

Lou

WACA 9519; Studying Pre-64 Model 70 Winchesters

![]()

November 1, 2013

Offline

OfflineLouis Luttrell said

Steve-Correct me if I’m wrong but is seems to me that the underside of the bolt body beneath the anti-bind lug, right where the S/N is usually inscribed, is commonly “roughed up”, especially in pre-war guns. Often looks like it was ground on by hand with some sort of rotary grinder. I don’t know if this had something to do with fitting the bolt to the action rails for slick operation, or what, but it seems commonplace.

Maybe to prevent the electric pencil from “skating” on the smoothly polished surface? But I was wrong in thinking it altered.

November 5, 2014

Offline

OfflineHi Clarence-

For a long time I also thought that meant a replaced/renumbered bolt. It sure does look like it!!! But you see it a lot on the early guns and always done in similar fashion, which suggests to me that it was a factory practice, not the coincidental action of multiple random non-factory gunsmiths choosing to renumber a bolt by first using a grinding wheel to remove the old one.

Still, I don’t know why they were done that way.  Given that the bolt was fitted to a receiver and not numbered until after the assembled gun was proofed and test fired, it seems unlikely that it represents the FACTORY’S way of re-cycling poor fitting bolts. If there was a need to replace a bolt they should have figured that out during function testing before the bolt was serialized…

Given that the bolt was fitted to a receiver and not numbered until after the assembled gun was proofed and test fired, it seems unlikely that it represents the FACTORY’S way of re-cycling poor fitting bolts. If there was a need to replace a bolt they should have figured that out during function testing before the bolt was serialized…

The ground surface is always beneath the anti-bind lug that rides in the left action rail as the bolt is cycled. I’ve wondered if maybe the factory didn’t intentionally leave a little extra metal on the surface of the lug where it would be in contact with the action rail and in the “shadow” of the lug on the bolt body. I’ve imagined that it was then up to the assembler to fit the bolt to the receiver, squaring up the fillet where the working surface of the anti-bind lug joins the bolt body and/or removing some metal from the bolt body at this point to ensure that the bolt moved back and forth without wobble or binding. Part of the reason these pre-war M70s were known for their slick operation… Pure speculation of course…  It seems sometimes whomever ground it for whatever reason was pretty heavy handed, as there’s often a rough “trough” right in that spot, where considerably more metal was removed that could have possibly been necessary…

It seems sometimes whomever ground it for whatever reason was pretty heavy handed, as there’s often a rough “trough” right in that spot, where considerably more metal was removed that could have possibly been necessary…

I really don’t know why it was done, but you see it a lot!!!

Best,

Lou

WACA 9519; Studying Pre-64 Model 70 Winchesters

![]()

November 1, 2013

Offline

OfflineLouis Luttrell said

Given that the bolt was fitted to a receiver and not numbered until after the assembled gun was proofed and test fired, it seems unlikely that it represents the FACTORY’S way of re-cycling poor fitting bolts. If there was a need to replace a bolt they should have figured that out during function testing before the bolt was serialized…

NM 1903 bolts were fitted by trying several different ones in the rcvr until one with optimal headspace & fit was found (by trial & error), then it was serialized; or so I’ve read. I’d like to drag out my one pre-war 70 to examine the bolt, but fighting the ongoing Nor’Easter takes priority. At least I still have power, which many don’t.

March 12, 2008

Offline

OfflineLouis Luttrell said

Steve-Correct me if I’m wrong but is seems to me that the underside of the bolt body beneath the anti-bind lug, right where the S/N is usually inscribed, is commonly “roughed up”, especially in pre-war guns. Often looks like it was ground on by hand with some sort of rotary grinder. I don’t know if this had something to do with fitting the bolt to the action rails for slick operation, or what, but it seems commonplace.

Lou, I agree completely. There is always a rough area just under the lug and adjacent to the machined flat surface. Keep in mind, these bolts started as rough forgings and were 1st turned in a lathe to get the body round on both sides of the anti-bind lug. After that they were machined in the lug area in a fixture with a milling machine. Since the area adjacent to the flat surface of lug was not able to be polished/blended with the large polishing wheels used, the as-machined, or rough ground surface was retained. They vary in roughness, and it seems the early rifles were the roughest of the bunch with the later ones being a bit better. I have a full set of drawings for every machining operation done on the receivers and bolts. It is really fascinating to look at all the pre-computer setups and operations done just to make a bolt. There were 8 separate operations in just drilling/tapping the ID of the bolt. There were 70 operations on the receiver from a solid block of steel to the fully machined receiver. This does not count the final polishing, heat treatment or bluing.

Steve

March 12, 2023

Offline

OfflineLouis Luttrell said

Steve-Correct me if I’m wrong but is seems to me that the underside of the bolt body beneath the anti-bind lug, right where the S/N is usually inscribed, is commonly “roughed up”, especially in pre-war guns. Often looks like it was ground on by hand with some sort of rotary grinder. I don’t know if this had something to do with fitting the bolt to the action rails for slick operation, or what, but it seems commonplace.

Pics below are of the underside of the bolt on S/N 4796, a type I-1 220 SWIFT Standard Rifle. Early 1937 gun pretty close to the OP’s rifle. I’m pretty sure this one does not have a replaced bolt. If it does than about half of my pre-war M70s have replaced bolts since many of them look pretty much like this…

I totally agree that the trigger on Marcus’ gun has been altered or replaced. If the sear engagement surface on the striker hasn’t been altered it should be easy/cheap enough to find a replacement factory trigger/sear if desired…

Lou

Now that is interesting! Thanks for sharing the bolt pictures.

March 12, 2023

Offline

Offlineseewin said

Louis Luttrell said

Steve-

Correct me if I’m wrong but is seems to me that the underside of the bolt body beneath the anti-bind lug, right where the S/N is usually inscribed, is commonly “roughed up”, especially in pre-war guns. Often looks like it was ground on by hand with some sort of rotary grinder. I don’t know if this had something to do with fitting the bolt to the action rails for slick operation, or what, but it seems commonplace.

Lou, I agree completely. There is always a rough area just under the lug and adjacent to the machined flat surface. Keep in mind, these bolts started as rough forgings and were 1st turned in a lathe to get the body round on both sides of the anti-bind lug. After that they were machined in the lug area in a fixture with a milling machine. Since the area adjacent to the flat surface of lug was not able to be polished/blended with the large polishing wheels used, the as-machined, or rough ground surface was retained. They vary in roughness, and it seems the early rifles were the roughest of the bunch with the later ones being a bit better. I have a full set of drawings for every machining operation done on the receivers and bolts. It is really fascinating to look at all the pre-computer setups and operations done just to make a bolt. There were 8 separate operations in just drilling/tapping the ID of the bolt. There were 70 operations on the receiver from a solid block of steel to the fully machined receiver. This does not count the final polishing, heat treatment or bluing.

Steve

That makes sense. I am pretty familiar with modern machining operations but didn’t think to consider this was turned and that protruding lug would prevent machining/polishing that area. Now I’m leaning back that this is the original bolt, and the engravers didn’t care to make perpendicular “1s”

Marcus

March 12, 2023

Offline

OfflineLouis Luttrell said

Hi Clarence-For a long time I also thought that meant a replaced/renumbered bolt. It sure does look like it!!! But you see it a lot on the early guns and always done in similar fashion, which suggests to me that it was a factory practice, not the coincidental action of multiple random non-factory gunsmiths choosing to renumber a bolt by first using a grinding wheel to remove the old one.

Still, I don’t know why they were done that way.

Given that the bolt was fitted to a receiver and not numbered until after the assembled gun was proofed and test fired, it seems unlikely that it represents the FACTORY’S way of re-cycling poor fitting bolts. If there was a need to replace a bolt they should have figured that out during function testing before the bolt was serialized…

The ground surface is always beneath the anti-bind lug that rides in the left action rail as the bolt is cycled. I’ve wondered if maybe the factory didn’t intentionally leave a little extra metal on the surface of the lug where it would be in contact with the action rail and in the “shadow” of the lug on the bolt body. I’ve imagined that it was then up to the assembler to fit the bolt to the receiver, squaring up the fillet where the working surface of the anti-bind lug joins the bolt body and/or removing some metal from the bolt body at this point to ensure that the bolt moved back and forth without wobble or binding. Part of the reason these pre-war M70s were known for their slick operation… Pure speculation of course…

It seems sometimes whomever ground it for whatever reason was pretty heavy handed, as there’s often a rough “trough” right in that spot, where considerably more metal was removed that could have possibly been necessary…

I really don’t know why it was done, but you see it a lot!!!

Best,

Lou

I might throw a depth micrometer on it, just in case someone else stumbles upon this thread in the future with the same question. On my bolt it does indeed seem deeper then necessary and that is what made me think it was ground.

Marcus

Log In

Log In