September 19, 2014

Offline

OfflineMike, I dare say I tried 5744 some in my .38-55. Accurate to a fault. Shot to shot velocity very tight, in the realm (if memory doesn’t fail) of 10 fps difference slowest to fastest. So, why do I NOT use it regularly? I always had about a dozen granules of unburned powder that gummed up the action rather quickly. Never found a way to eject brass without granules falling into the action. I even tried the ground up styrofoam or some such filler to see if it would burn more completely. Nope. In the end I didn’t think it worth the efforts to keep my rifle functioning regularly (seemed to me the trigger got the worst of it). Hope you find it improved or at least tolerable for you. Its a great powder in its own right tho. I still prefer 4198 by whomever(IMR, Hodgden). Tim

March 31, 2009

Offline

OfflineTXGunNut said

Chuck-

I’ve had some success with 3031 in other cartridges, as I recall it and RL7 perform well for me in the 30WCF, 32Spl and 35 Remington (and maybe a few others). In my experience it works best at a bit higher pressures in medium sized cases utilizing a bottleneck. The 45-90 is a Holy Black cartridge for me so I have very little experience with 3031 in that cartridge. IMHO smokeless powder makes no sense in a case that big. I’ve had some success with BP in the 38-55 but this project involves smokeless powder and velocities somewhat above what BP can deliver and less than what seems to be an optimal 3031 load. I don’t doubt 3031 will work in this cartridge but I think I want to work a little more with 4198 and maybe 5744 before trying 3031 again.

Mike

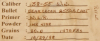

5744 has become my lazy powder. It is easy and I’m lazy. I dug out a box of my 38-55’s. And also found a Hodgdon Cowboy Action loading pamphlet. This one shows pressures.

November 7, 2015

Offline

Offlinetim tomlinson said

Mike, I dare say I tried 5744 some in my .38-55. Accurate to a fault. Shot to shot velocity very tight, in the realm (if memory doesn’t fail) of 10 fps difference slowest to fastest. So, why do I NOT use it regularly? I always had about a dozen granules of unburned powder that gummed up the action rather quickly. Never found a way to eject brass without granules falling into the action. I even tried the ground up styrofoam or some such filler to see if it would burn more completely. Nope. In the end I didn’t think it worth the efforts to keep my rifle functioning regularly (seemed to me the trigger got the worst of it). Hope you find it improved or at least tolerable for you. Its a great powder in its own right tho. I still prefer 4198 by whomever(IMR, Hodgden). Tim

Tim-

I’m a big fan of 5744 as was MLV. It is very well suited to many of the cartridges I love. My issue is that I spend too much time cleaning my rifles after I use 5744 in these cartridges. It makes Unique (lovingly called “flaming dirt”) seem clean by comparison. I don’t know it it’s the powder and bullet lube combo or what but I spend days cleaning the resulting tar out of my bores. I haven’t noticed the unburned powder but that would be a red flag for me. In my experience 4198 has been a near twin to 5744, without quite as much scrubbing. I’ve used it occasionally over the years but have been using it more lately; so far, so good.

Mike

November 7, 2015

Offline

OfflineChuck-

I like your 255gr load. My “255” mould actually results in a finished bullet weight around 263 IIRC so your data is helpful. I don’t have much use for cowboy action load data, they have a great sport and our hobby has benefitted from it but their goals and expectations differ from mine. Their game favors light recoil and does not require the accuracy I’m looking for. On top of that can’t afford the clothes they like to wear.

Mike

March 31, 2009

Offline

OfflineTXGunNut said

Chuck-

I don’t have much use for cowboy action load data, they have a great sport and our hobby has benefitted from it but their goals and expectations differ from mine. Their game favors light recoil and does not require the accuracy I’m looking for. On top of that can’t afford the clothes they like to wear.

Mike

The part I found interesting is the CUP pressures listed/fps/grains. Not all powders will create the same pressure at the same speed. With some powders you may have to load to a slower speed to keep the pressure safe. I know that these guys don’t shoot hot loads but if you look at a normal loading manual you’ll see the Max load with one powder will be at a different speed than another. So loading to a specific speed does not indicate safe pressures.

November 7, 2015

Offline

OfflineAgreed. The more I learn about powders the less I know about them. If we could see a pressure graph during load development that would bring a whole new dimension to reloading! I feel sure there’s an MIT grad student/precision shooter working on a portable instrument that will do just that.

Mike

March 20, 2010

Offline

OfflineMike,

Ive used IMR 3031, 5744, SR4759, & Swiss 1.5 shooting a 256 grn cast GC bullet for my 38-55 carbine and rifles.

I prefer 5744 (22 grn) in terms of consistent velocity averaging 1580 fps from a carbine and 1625 from a 26″ rifle.

With IMR 3031, 28.5 grns powder at 1510 fps from a carbine and 1580 from a 26″ rifle.

If you have some, the SR 4759 works well with this bullet at 19.5 grn powder, carbine 1565 fps, 26″ rifle 1605 fps.

And the Swiss 1.5 with 49 grns powder from a carbine is 1301 fps, from rifle 1374 fps.

Ive shot 5 shot groups with each of these under 1.5″ at 50 yards, some better than others depending on the shooter.

Caveat: What works best for me may not be best for others.

Chris

1892takedown @sbcglobal.net ......NRA Endowment Life Member.....WACA Member

"God is great.....beer is good.....and people are crazy"... Billy Currington

November 7, 2015

Offline

OfflineThanks, Chris-

I don’t know why I haven’t had much success with 3031 in my rifles. Maybe it’s because the loads I’ve tried were 29-30.5 grains so it’s worth another look. Perhaps it’s because the 5744 and now 4198 works so much better. My first loads for this cartridge were with Olde Eynsford but was only able to get 43 or 44 grains under the bullet I was using in the Starline cases. I didn’t catch on to 4759 before its demise so won’t get to venture down that path.

I’m headed to the range (after a bit more coffee!) but I’m not optimistic. In my last loading session I felt like I was using two different lots of brass as the resistance observed flaring the cases was quite different. I found these cases already cleaned and sized and there was a time I was experimenting with partial resizing so this could be interesting. My .381 bullets distort the case necks a bit on some so I may need to re-visit the partial resizing idea. This old 1894 has a nice trigger to go with the new sight package so it’s very enjoyable to shoot.

Mike

March 31, 2009

Offline

OfflineTXGunNut said

In my last loading session I felt like I was using two different lots of brass as the resistance observed flaring the cases was quite different. I found these cases already cleaned and sized and there was a time I was experimenting with partial resizing so this could be interesting. My .381 bullets distort the case necks a bit on some so I may need to re-visit the partial resizing idea. This old 1894 has a nice trigger to go with the new sight package so it’s very enjoyable to shoot.

Mike

Do you ever anneal the necks? I did an experiment with a few hundred cases checking the rebound of the neck diameter after sizing. Things really got bad after sizing a case and not annealing after about 3 times. Anytime I want the best accuracy I anneal each time before I size. Plinking, who cares.

November 7, 2015

Offline

OfflineChuck-

I don’t think loading this cartridge works the brass enough to harden it much. I certainly could be wrong as today’s range trip resulted in pronounced vertical stringing; 1.5-2″ wide groups 3-6″ tall. I’m thinking that was a result of the different sizing processes. I’ve long resisted getting into annealing but with today’s brass prices and availability I need to change my thinking on that. I’ll analyze thigs more closely after my nap. I shot up all my ammo (over 50 rounds) so that I could get a fresh start. Good news is sights are well-regulated, new rear aperture size works great with the Lyman globe front sight and it was a great day for some trigger time! Bore wasn’t especially dirty after around 100 rounds so I’d say the IMR 4198 powder is even cleaner than I expected.

Mike

April 15, 2005

Offline

OfflineTXGunNut said

Bore wasn’t especially dirty after around 100 rounds so I’d say the IMR 4198 powder is even cleaner than I expected.

Mike

Mike,

I once fired (300) consecutive 222 Rem Mag reloads over the course of nearly a full day of shooting (while exterminating Whistle Pigs in southern Oregon) when I was still using IMR 4198 for that cartridge. The bore in my rifle (a Remington M-700 BDL Heavy Varmint) cleaned up very quickly. I personally like the minimal cleaning required when shooting the 4198 powder.

Bert

WACA Historian & Board of Director Member #6571L

November 7, 2015

Offline

OfflineBert-

I wasn’t expecting to be THAT much cleaner, quite honestly. Even throwing cast bullets and the required lube into the equation the fouling was minimal.

Mike

April 15, 2005

Offline

OfflineTXGunNut said

Bert-

I wasn’t expecting to be THAT much cleaner, quite honestly. Even throwing cast bullets and the required lube into the equation the fouling was minimal.

Mike

IMR 4198 is a fantastic powder for the 222/223/222 Mag group of cartridges, providing for excellent accuracy and noted for being very clean burning. Frankly, it is the best “all around” rifle cartridge powder in my opinion. The vast number of rifle cartridges that can be reloaded using it is second to none. The fact that it can be used for a very large number of the older black powder cartridges adds to its appeal.

I have to thank my grandfather for teaching me about its wonderful attributes back in the early 1970s when he was reloading for his triple-deuce mag rifle (an original Remington Model 722) with it. For some reason (my dad is to blame) in later years we/I switched to IMR 4064 for the triple-deuce mag, but just recently, I went back to using 4198 for this load in my grandfather’s rifle (that I inherited back in 1999).

WACA Historian & Board of Director Member #6571L

November 7, 2015

Offline

OfflineBert-

I’ve been using H4198 and IMR4198 on occasion for quite some time but haven’t understood its versatility and other attributes until recently-thanks, Bert! My grandfather used gunpowder for launching anvils but his exact loads were never passed down and in any case they would NOT be disclosed here! Frank Barnes was a big fan of 4198 for dozens of cartridges, including many of our favorites. For some he listed no other smokeless powder loads.

Chuck-

I loaded 15 rounds (10 PB, 5 GC) tonight after sizing and expanding the brass to give uniform tension (hopefully) at the neck. I’m thinking I need to back off the sizing die a bit more but will try one change at a time. It seems my groups contain somewhere around 15% high flyers in each of the three loads that show promise so I’m going to focus on case prep.

Mike

March 31, 2009

Offline

OfflineTXGunNut said

Chuck-

I don’t think loading this cartridge works the brass enough to harden it much. I certainly could be wrong as today’s range trip resulted in pronounced vertical stringing; 1.5-2″ wide groups 3-6″ tall.

Mike

Your brass gets blown out against the chamber walls and then relaxes a bit during each firing. Then you size it down and after that you run the expander through it. After that you seat the bullet. So each cycle the brass is moved in and out more than twice. Now figure out how many times this brass has been fired. Add the heat and pressure the case sees. Size some brass then measure the neck diameter. Let it sit for a day or so and then remeasure it. Annealed brass will hold it’s setting. Often times work hardened brass won’t. If you measure the neck diameter of a sized case then measure it again after seating the bullet this gives you the neck tension in .001 of an in. I usually use .002″ of neck tension for my target loads and .003″ for my other loads. One other thing is how much of the bullet is being grabbed by this tension. I don’t know how to figure the pressure in square inches. So with .002″ of neck tension if my brass rebounds .001″ after sizing I have lost 50% of my neck tension.

November 7, 2015

Offline

OfflineYes, for the most part I’m aware of how brass behaves during shooting and reloading. With this cartridge and the 45-70/45-90 I’ve learned to only size the brass enough to hold the bullet. Most die sets size the brass too small at normal settings. Some of the brass I used last week was found when I sorted through every last bag, box, tin and coffee can in my reloading room recently. Obviously I mixed in some brass that was resized awhile back. I’ve never re-measured sized brass after a few days, may try that. Awhile ago I learned to back out my sizing die to keep it from working the brass as much. (With the 45-70 and 45-90 I use a neck sizing die and expander.) This rifle makes me toe the line, it has a somewhat tight chamber and the .381″ bullets (required for her .380″ bore) in Starline cases don’t leave much room for creativity. It’s very tempting to cast some .377″ bullets from 20-1 alloy and see if 4198 will bump it up enough to engage the rifling.

Mike

November 7, 2015

Offline

OfflineI’m glad we talked about sizing brass, Chuck. I was sizing the Starline brass a few thousandths more than I remembered. I may have set the sizing die for the Winchester brass I used awhile back. I backed off the sizing die a bit more and sized a bunch of brass I just emptied. Groups I shot today were still twice as tall as they are wide but it seems I’m moving in the right direction. I have some brass in the cleaner now that may be kinder and gentler to my precious cast bullets. Only problem is the decapper in my RCBS Cowboy dies can’t reach the primers now so I’m basically neck sizing and running the cases thru a decapping die. This is starting to remind me of my 45-70/45-90 adventures.

Mike

1 Guest(s)

Log In

Log In