Howdy Folks,

I am a new member to this forum and have done quite a bit of anonymous reading here for quite a while now. I have learned a lot and enjoy what people who know what they are talking about have to say. You are certainly a most knowledgeable group and always seem to have the answers! Thank you!

I have a rifle that I would like your opinions/comments on, and I know the general feelings most collectors have regarding the altering of vintage factory issued arms, and rightly so. The alterations done to this rifle were likely done in the early to mid 1940’s, a bit before my time. I know who built the stock, but don’t know who did the metal work.

The rifle was owned by John L. Hutton, the Hutton’s were our family’s next door neighbors from the later 1950’s, and was purchased by my dad from his widow (Catherine) in 1965, when John passed away. The stock is stamped HUTTON within the inletting, just behind the recoil lug. I know that John worked for Griffin & Howe and for Col. Townsend Whelen at The National Target and Supply Co. as a stock maker from the later 1930’s into the early 1940’s.

The action of this rifle was shortened from it’s original 7-1/2″ between front and rear guard screws to 6-3/4″. The bolt, follower, magazine box and floor plate have all been similarly shortened. The action serial number is 21312 and dates from either 1938 (WACA and BlueBook/Fjestad) or 1939 (George Madis). The .220 Swift barrel is stamped either 5T or ST (not sure which), 22S and 42 on the bottom, with what seems to me to be the normal sort of roll stamp on the top of the barrel. I gather from my reading here that the barrel was bored and rifled for .22 caliber, and that the 42 indicates the year of the barrel’s manufacture. The significance of the 5T or ST and the S following the 22 are unknown to me. The barrel is 25-5/16″ long, 1.140″ in diameter at the chamber/action face, 0.582″ in diameter at the muzzle, and the center of the barrel boss is 4-1/4″ from the front of the action face.

The action was shortened right through where the WINCHESTER logo is on the LH side of the action. This logo appears to me to have been engraved, rather than roll stamped, and was done after the action was shortened. However, the words -TRADE MARK- appear to be roll stamped. The action does not appear to me to have had the original WINCHESTER logo ground off because the contours seem too uniform. I can tell where the cut/weld was done on the action, but can not see any such indication on the other shortened parts. Any ideas???

I have taken many photos of this rifle and it’s stock, too many to post all of them here. If you have an interest in seeing the rest of them, and if it is OK to post a link for you to see them on FLICKR, they can be seen here:

http://www.flickr.com/photos/cgm-gunstockcheckering/albums/72157692997236912 (click or cut and paste this link into your browser)

Thanks in advance for your time and interest!

Clint M.

Hello Clint,

The “ST” stamp on the barrel implies Stainless, and I believe that the “S” after the 22 is short for “Swift”. Serial number 21312 was applied to the receiver in late September, 1938. I have no idea about the shortened action.

Bert

WACA Historian & Board of Director Member #6571L

Have heard of shortening rcvrs. to reduce bolt throw for the .22 Hornet, but for a cartridge as long as the Swift, seems like a fantastic amount of work for minimal gain. However, the folks who fancy custom rifles with special metal-work would probably find such a re-worked 70 appealing.

Howdy gents,

Bert, thanks for the explanation of the ST and S. I appreciate that very much as it adds to my understanding of what I have.

Clarence, thanks too for chiming in! Yes, it no doubt was a lot of work and I tend to agree that the gain was minimal. I am sure that others also will be appalled by such willful desecration (and please keep in mind that I am just the current care taker), however don’t most custom rifles have at least some degree of metal rework done to them? I guess it all is in what floats your particular boat!

Thanks fellas!

Clint M

Clint M said

I am sure that others also will be appalled by such willful desecration (and please keep in mind that I am just the current care taker), however don’t most custom rifles have at least some degree of metal rework done to them?

All high-grade custom guns are expected to have fancy wood & checkering; that’s the “entry-level requirement” in that genre. But to break out of the pack, and be considered really “special,” metal work of some degree of complexity is the next step in the demonstration of professional mastery.

Work done on this gun, while of questionable practical value, is very far from “willful desecration”! Shouldn’t forget the Model 70, for all its excellence, was a mass-produced firearm, not a Newton, Ross, Springfield Sporter, or other limited production item.

Clint-

What a beautiful custom pre-war M70!!! You are lucky to be the current caretaker. I would agree with Clarence that the work on this rifle by a well known stock maker is far from a desecration.

Bert is correct of course that “22S” is the common chamber inspection stamp for 220 SWIFT, ST denotes stainless steel, and 42 is the year of barrel manufacture. The receiver SN 21312 was applied in 1938, so it predates the barrel by a couple of years. The barrel looks to have its original front sight ramp which would suggest that it is still the full 26″ length.

Anyway, here’s my question (for Bert or anyone else)… Looking at the photos on flickr (Clint, thanks for posting them BTW) it appears the both the barrel AND receiver have an “oval P” stamp (mail order proof mark?). Am I right that’s what this is, Bert? I’ve never seen the mail order proof on a receiver before – only barrels. If that’s what it is, there is always the possibility that this was never a factory assembled rifle, rather that someone (probably with friends at the factory) “mail ordered” the action (which was then customized) and barrel as separate parts. Which really isn’t “desecration” at all if the rifle was made this way from the start.

Related (trivial) question is that in the flickr photos on both the barrel and receiver the “WP” and “oval P” proofs appear rough and unpolished. The barrel makes sense, since the proofs were applied to parts after finishing so should be rough. The receiver is curious, only in that if it was sent out as a standard length finished receiver, then cut/shortened, it would have to have been refinished after modification. Which I would have expected to cause the proofs to be polished over.

Any thoughts? Am I just confused?

Best,

Lou

WACA 9519; Studying Pre-64 Model 70 Winchesters

![]()

Lou,

It appears that both the barrel and the receiver were mail order parts. I have seen less than a handful of receivers with the mail order (P) proof mark on them. It is possible that Winchester shortened the receiver on special order, then mailed it out.

Bert

WACA Historian & Board of Director Member #6571L

Hi Bert-

You raised EXACTLY the point I started thinking about when I saw the mail order proofs.  Is is perhaps possible that the “gunsmith” that made the shortened action was in fact Winchester? In which case there would be no desecration at all.

Is is perhaps possible that the “gunsmith” that made the shortened action was in fact Winchester? In which case there would be no desecration at all.

Hi Clint-

I haven’t studied your excellent detail photos as closely as I should, but are you sure the receiver has been cut/shortened (as opposed to having been milled that way)? True, the ‘Winchester’ roll mark on the left of the action is not centered on the loading port as is normal, but the coarse grinding marks on the action flats below the stock line look uninterrupted. My eyes aren’t quite good enough to make out what you’re indicating with the yellow arrows in the detail photos on flickr, I assume that’s showing were the cut/re-weld was done…

Ditto where was the bolt body? The anti-bind lug of the bolt is further forward than normal indicating that the bolt body is shortened in the same place as the receiver. Compare your photo below to the underside of the standard M70 bolt next to it. The electro penciled bolt serial number is in the right place on your action. Out of curiosity, is it also still rough (not polished over?). Normally, bolts were serial numbered to the rifle only after headspace was determined (which required a barrel of course).

The floor plate is interesting in that it bears the “triangle I” pre-war Winchester inspection stamp. Certainly that part would have been milled special for this project, yet it has that Winchester factory stamp. Just curious…

Finally, do you happen to have a full length photo of the assembled Hutton rifle you’re be willing to post? I’d love to see that that “short” action and long barrel looked like in that stock.

Best,

Lou

WACA 9519; Studying Pre-64 Model 70 Winchesters

![]()

Beautiful rifle. Beautifully done. I would enjoy owning it.

As I scrolled through the photos, the most tantalizing question that lept out at me was whether Winchester shortened the action. I think there is ample reason to speculate this may be true. Unfortunately, this line of thinking will likely never be proven. The fact that the Winchester lettering has been returned to the action is intriguing. One thing this rifle has going for it is much of it’s history is known – dating decades back to when the stock was done. This is not some rifle that appeared out of no where and is now offered for sale at a high price. If someone made this rifle up last year (with profit in mind), one can understand the motivation to apply the Winchester name and Trademark stamping. But many decades ago when this rifle was made? We know now that many fakers possess what is necessary to reapply factory markings. But way back then? If Winchester didn’t apply those markings, who did? And why was it important to do so?

The lack of obvious signs of shortening on the other action parts is thought provoking as well.

A deep and very intriguing mystery. Thanks for posting. And again, a beautiful rifle as well as something that arguably exceeds the original. I’ve always like the pre-64 M70, especially in the .375 and .300 H&H. The action was well-mated to those cartridges. But using that same long action for the shorter cartridges (the .22 Hornet – good grief) sure blew some of the aesthetics and practicality for me.

steve004 said

But using that same long action for the shorter cartridges (the .22 Hornet – good grief) sure blew some of the aesthetics and practicality for me.

Yes, if Winchester engineers wished to experiment with a shortened action, you’d think the popular Hornet would have been their prime “excuse.” This was something Sedgley began doing with ’03 actions shortly after the Hornet was introduced. To do it for a case as long as the Swift makes a lot less sense, which is why I’m inclined to be skeptical of this being a factory job; though if it were, this shortened action would leap into the stratosphere of M70 rarities!

Since there’s no way to verify it’s status as a possible factory job, can John Hutton’s career be researched? Do other guns built by him exhibit advanced metal-working techniques?

Theorizing on the potential history is fascinating. Who knows. I was leaning toward if the shortening of the action was done by the factory, the action was ordered that way and sold as an action only. But that’s about as far from a standard special order feature as one can get. Back to who knows. Maybe there was discussion among employees from the factory and people on the outside. This must have happened all the time. Maybe Winchester had worked on shortening an action and decided not to proceed (as we know they did not put a short action into production). Through discussion, it was somehow communicated they had the action – and agreed to part with it. Again, maybe some sort of special connection was involved. Some sort of idiosyncratic anomaly. Sometimes paperwork (e.g. invoices; correspondence) existed, but more often than not, such things are lost to time.

Clint was having trouble posting, so I offered to post his reply on his rifle. He first told me about this rifle probably 20 years ago, but did not have it in his possession until about a year ago. I hope to make it over to his house in the near future to examine in person.

Steve

Howdy gents,

Boy, it is hard for me to keep up with replying to you guys, but here goes. I have taken some additional photos and added them to the FLICKR page with the other photos of my Hutton rifle. They appear at the bottom of the second page of photos. The link appears in my initial post, above.

(For those who may not be aware of exactly how looking at FLICKR posted photos works, depending on what browser you are using, you can right click on any image on those pages and a menu box may appear. If it does, try clicking on ‘open in a new window’, and that image may appear on a grey background. The curser turns into a magnifying glass with a ‘+’ where the lens is. Click anywhere on the image and it enlarges, and moving the curser (magnifier now with a ‘-‘ where the lens is) around lets you view any part of the enlarged image. Clicking again may return the image to its normal size, and clicking ‘<- back to album’ at the upper left may take you back to the rest of the images. Like I said, this may depend on your browser!)

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Clarence – My use of ‘willful desecration’ was more tongue-in-cheek than in earnest, sir. I know all too well how ‘serious collectors’ view any modifications to collectable arms, a concept with which I agree to a large extent, however may not totally subscribe to in all cases. I am not a ‘serious collector’ myself, but consider myself to be a curious user, always eager to learn more. Thanks for your comments!

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Louis Luttrell – Thanks to you for what you have added! I gather that barrels of this caliber and type are supposed to be 26″ long. How is that measured? This one is 25-5/16″ from the front end of the muzzle crown to the front of the action. Would the 26″ you mention be the OAL of the barrel before it is screwed into the receiver? Curious minds want to know!

It was my great pleasure to be able to post something here of meaning and interest at last, so you are quite welcome!

Regarding the “WP” and “oval P” proof marks, they are still sharp and I can feel raised edges with my finger moving across them on both the barrel and action. Two close-up pictures follow:

https://farm1.staticflickr.com/977/28237014238_7fec8b9627_z_d.jpg

https://farm1.staticflickr.com/903/28237009648_0df85924bd_z_d.jpg

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Bert – Thank you, I had never heard of mail order parts before, especially those having a special proof mark! Funny that you should mention the possibility that Winchester could have done the shortening of the action. In talking with my younger brother about this rifle between one and two years ago, he told me that he had always understood that Winchester had done this work. I thought, yeah, right! When I asked him how/who/where that tidbit came from, he was unable to recall, saying only that is what he had always believed to be true. So, I then also asked my dad about this and he had no recollection of ever having heard that himself about this rifle.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Louis Luttrell – Yes sir, I am quite sure that the action has been cut and welded, as little voids from surface cavitation (my dad was also a welder, among many other things!) are evident on it, which I did try and point out (you were right, sir!) using the yellow arrows on some photos. Here is another photo showing what I believe to be surface cavitation, see yellow arrows again:

https://farm1.staticflickr.com/904/42109969461_c30ca3b1aa_z_d.jpg

Yes, the coarse grinding marks along the flats of the action do indeed appear to be uninterrupted. Could this imply that the raw action forging (correct term?) could have been cut apart and then welded before any of the surface grinding, polishing and roll marking and proof marks were applied?

I posted earlier that the “WINCHESTER” logo looked to be engraved in the steel, instead of roll marked. I took some more very close-up photos of that feature, and now am not so sure, not having another Mod.70 to compare it to. A couple of those follow:

https://farm1.staticflickr.com/832/28237005768_94d3e340a6_z_d.jpg

https://farm1.staticflickr.com/827/42109989071_369841c7e2_z_d.jpg

I can a slight surface roughness with my finger going over the electro-penciled serial number of the bolt, but that may just be the small pits I feel and not the numbers. Hard to tell with old finger tips! A closer-up photo of that follows too:

https://farm1.staticflickr.com/943/41391244844_6ae78acd46_z_d.jpg

Someone else suggested that if the bolt were shortened, it could have been cut and welded under the extractor claw ring, where it wouldn’t show. But now that I see the bolt photos you have added, Louis, that does not seem possible either unless a new gas escape hole was drilled later.

The floor plate did not look to me as if it could have been shortened from a longer original, too many surface features on the inside surfaces to deal with. There are no signs of bolt shortening that I can see, and the same for the magazine box and follower. Those parts all look unaltered to me at least.

And here are the full length photos that you requested, Louis:

https://farm1.staticflickr.com/824/42109983221_8587d69ac1_z_d.jpg

https://farm1.staticflickr.com/976/42109979231_d04e5044a6_z_d.jpg

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Steve004 – You are welcome too, sir! Thanks for reading and looking. I love a good mystery!

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

clarence – I have written all that I know about John Hutton on my FLICKR collection page for this rifle. To read it, click on the ‘Show more’ just under the main title and first couple of sentences in the upper center of the page. Link appears in the top post, above.

What was written above originally in this post was abbreviated. From what I know from personal conversations with John Hutton in the early to middle 1960’s (when I was a teenager), and from what I have read about him now in Michael Petrov’s two books (Custom Gunmakers of the 20th Century, Vols. 1 & 2) and Townsend Whelen’s book, Mister Rifleman, which mentions three rifles stocked by him, no mention was ever made anywhere about his ever doing any metal work that I am aware of, only that he was a stockmaker. Since he was the machine shop supervisor for the National Bureau of Standards when I knew him, he must have learned something somewhere about precision metal work between the mid 1940’s and the later 1950’s. He owned no metal working tools when he passed away other than a few measuring instruments, which I now have too.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Steve004 – Yes, it is fascinating to ponder the ‘what if’s’!

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Now, I have another question of my own for all of you. Take a look at the following two photos:

https://farm1.staticflickr.com/976/40818614535_906149b8ba_z_d.jpg

https://farm1.staticflickr.com/827/40818359145_73ddc51d5f_z_d.jpg

This rifle’s action was made in 1938, the barrel in 1942, 4 years apart. Note that this stock has had a block of wood inset into it in the chamber area of the barrel channel. I doubt this was an inletting mistake. What could the reasons be for this? That the stock was made to fit this specific action, there is no doubt. When the action was modified, we can’t be sure, other than probably sometime after 1938. This action and barrel could not have been mated before 1942, right? Could this action originally have had another larger diameter barrel in the chamber area and the present slimmer one been fitted in 1942, or later? Oh, man, do I wish it could talk!! Thanks everybody!

Best regards….Clint M

Hi Clint-

Thank you for the follow-up and the added photos of the entire rifle. I’m sure that all mysteries will be resolved when seewin, given his profession, gets to examine the rifle.

To try and answer a couple of your questions… Barrel length is from the muzzle to the bolt face, including the threaded portion. So a good way to measure is to insert a cleaning rod into the muzzle with bolt closed (unloaded of course), mark where it stops, and measure. Based on your measurement, the photos of the ramp, and the placement of the proof marks, I’d say that is an unaltered full 26″ length 220 SWIFT barrel.

The “roughness” of the proofs is evidence that they were applied after the metal was polished/blued. Bolts didn’t get electropenciled until the factory assembler fit the barrel and adjusted final headspace. The ‘WP’ proofs didn’t get applied until after the fully assembled/finished rifle was proof tested. Hence on a factory assembled M70 they are the only marks that aren’t polished over (although the bolt serial number may get worn down from rubbing on cartridges in the magazine when the action is cycled). What makes this curious is that cutting and welding the action would require that it be blued AFTER shortening. So the rough receiver proofs suggest that this was NOT a case where someone took a finished receiver from a completed rifle and then shortened it. Unlike proof marks, serial numbers were applied in the polishing room that got newly milled receivers ready for finishing. So my best guess is that a finished 1938 receiver was retrieved from the parts bin (probably sometime in 1942 or shortly thereafter), shortened, then (re)finished prior to ever having been assembled into a rifle and proof marked. Fascinating to speculate…

I also can’t figure out how a standard bolt was shortened. I suppose if it were cut under the extractor collar and the gas relief port redrilled it would succeed in moving the anti-bind lug forward. It may take seewin pulling off the collar to answer that one? An alternative explanation would be that the bolt body was originally made the way it is now, which would imply the factory did it b/c nobody going to the trouble of making the bolt from scratch would have added all the Winchester inspector stamps.

The factory ‘triangle dash’ inspection mark on the floor plate is also curious. If the part was made outside the factory by modifying an existing floor plate it might carry that mark, but as you say it does not look like it was made by modifying a standard part. The magazine box is a rather simple thing to make, and the one on your rifle was made special for the project. The magazine box used on the regular Swift had two slanted partitions to shorten its internal length and facilitate feeding of the semi-rimmed Swift case. Those partitions produced crimps in the magazine box that would be visible on one end or the other had a Swift magazine been shortened, and the “plain” standard magazine box has a vertical crimp in the side that would be evident.

I attempted, with little success, to take a close-up of the ‘Winchester – Trade Mark -” on another M70 (from 1946) for comparison. Not really good enough, but below:

All-in-all, I’d be inclined to speculate that back in ’42 Col. Whelen (or someone else with a lot of contacts inside the factory) got them to make up a “Swift-sized” M70 receiver, install a regular .220 SWIFT standard weight stainless barrel, and ship out the barreled action after proof testing. Hence the ‘WP’ proofs and the ‘mail order proof marks’??? The action then came to Mr. Hutton for stocking. There was no M70 barrel contour that would have been larger diameter at the breech but the same dimensions elsewhere. The exterior dimensions of the standard barrel contour did not change from 1936-63.

Guess we’ll just have to wait until seewin answers all!!!

Lou

WACA 9519; Studying Pre-64 Model 70 Winchesters

![]()

As you all acknowledged Winchester experts contemplate ‘hands on’ forensics, I’m conjuring the external, market & political forces versus the time, effort – resource dedication and particularly motivation to create such a rifle. The 1942 perspective of ‘at war’ in Europe horrifically slammed to America at war! From heavily into Lend Lease, transformed to war footing on the home-front with war materials, top priority.

Just not any kind of situation seeming compatible with the firm ‘turning-to’ toward any such sort of, let’s face it, fanciful commercial project. And even greater question, to what purpose? Seeming unlikely Colonel Whelen or about anyone with such influence, so out of touch with priorities, putting personal use/connects/benefits toward such project in those dark hours!

By latter, 1941, Remington already in Springfield ’03 war production. Winchester tooling up for M! Carbines and in production of M1 rifles. A bit amazing to contemplate any resources being diverted to ‘experimental sporting rifle’. At worst, someone’s, internal or external, personal project in 1942. At best, perhaps in 1938 a project started with subject action actually fabricated then and shelved. Win folk contemplating such short action, then project abandoned/postponed. At least seeming more likely than full-on ‘scratch production’ in ’42. Also, the action components the only really critical pain in ‘A’, work. Others largely falling into place. Though admittedly the stock also remaining an issue, such seeming not a tenth of work producing special action!

My best guess, ‘aftermarket’ rifle. No desire to burst balloons. Yet not subscribing to achieving ‘lift’ with hot gas! Great to contemplate some sort of Winchester venture. But without hard documents supporting, essential “provenance” not occurring. Seems to me statistically, ‘aftermarket work’ in the ‘simpler explanation, Occam’s razor honing probabilities here. Of all questions, the “why then” the most intriguing and least likely to suggest a ‘factory work’ positive answer.

Now evening late! To bed, hazarding without edit.

My soapbox-windy, ‘outside the box’, era take.

Hi iskra-

Always good to hear from you… You’re right, it’s always wise to toss a “wet blanket” when confronted with “hot gas”…

Provenance, rather than speculation, would be vital if the subject rifle were being offered for sale as a rare factory custom, but as far as I can tell that’s not the case here. We’re just puzzling over the weird hieroglyphics Winchester stamped on various parts of its products at different stages of manufacture.

I hope you didn’t misunderstand what I meant when I said “sometime after 1942″… I didn’t mean to suggest that work on the rifle (factory or otherwise) was performed during the dark days of WWII. If I had to speculate (there’s that word again!!!) I would have said maybe ’46. Most of the M70s the factory assembled in late ’45 and early ’46 were built from pre-war parts and ’42 barrels are pretty common on early post-war M70s (particularly anything that isn’t .30 GOV’T’06 or .270 W.C.F.). I’m sure that converting the plant back to civilian production AND changing over tooling to produce the type II action took time, during which the assemblers were kept busy using up old parts and the machinists may have (to some greater or lesser extent) been in limbo…

On the whole I’d agree that the action of this rifle is most likely non-factory custom work, but my main (if wholly speculative) argument is that if the factory wanted to make up a short action they had the where-with-all to mill the receiver from scratch rather than cut/weld one.

Cheers, Lou

WACA 9519; Studying Pre-64 Model 70 Winchesters

![]()

Hi Louis and iskra,

Thank you both for your further commentary, gents. I appreciate it a lot and am learning, for sure.

Louis- thanks for the barrel length clarification. I had suspected that it was the OAL rather then what was left sticking out of the action, which seems the more common way to reference almost everything else.

In looking at the photos of the words –TRADE MARK– that I added later, and comparing them to the photo you posted, it seems like on my rifle these words may have been hand stamped because the letters in ‘TRADE’ don’t appear to be in line well, and that a lot more pressure was put on the last bar after the word ‘MARK’, it looks tapered. Curious!

Regarding the shortening of the bolt, I now notice in the first photo of the bolt at the top of the page, that there are what looks like a short row of pits half way between the gas port and front end of the anti-bind lug. This could suggest that this is where the bolt could have been shortened, or do all bolts have some pits in there surfaces?

Best regards……..Clint M

Hi Louis and iskra,

iskra- what you said makes a lot of sense, sir, and I don’t take your view as being a wet blanket at all. I am grateful to learn whatever I can about this rifle, come what may. It’s been in my family since 1965 and now I have it, so it isn’t going anywhere during my lifetime if I can help it.

Best regards……Clint M.

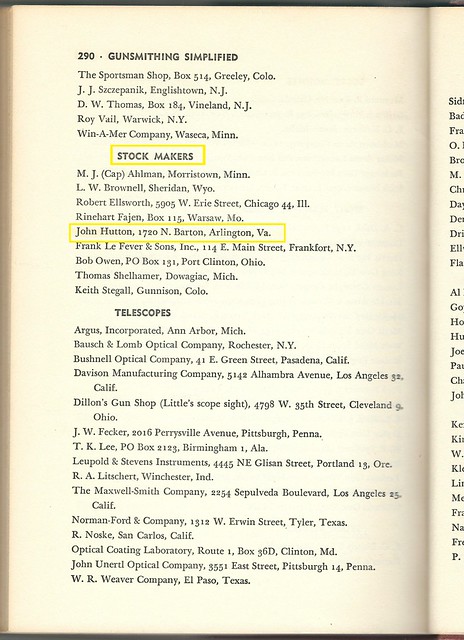

I can add one more small piece to the puzzle regarding John Hutton. I found him mentioned in Harold E. MacFarland’s book, Gunsmithing Simplified, my copy is a third edition printing in 1959. John Hutton is listed as a stock maker on page 290. This book was first printed in 1950, so I assume that Hutton’s mention also appeared in that first edition, but don’t know that for sure.

The address given is the same as in Michael Petrov’s book, so one may surmise that Hutton could possibly still have lived there up until at least shortly before 1950. Also, since no mention is made as to Hutton’s last known employer, The National Target and Supply Co., can one assume that he was working on his own as a stock maker at that point? Above, I mentioned that John Hutton was my next door neighbor, and this would have been from 1958 to 1965. Again, no mention of him doing any metal work, just that he made stocks. Thanks for your interest!

Best regards……Clint M

Clint M said

in post #16

Louis-

Regarding the shortening of the bolt, I now notice in the first photo of the bolt at the top of the page, that there are what looks like a short row of pits half way between the gas port and front end of the anti-bind lug. This could suggest that this is where the bolt could have been shortened, or do all bolts have some pits in their surfaces?Best regards……..Clint M

Louis, in regards to the shortened bolt, ‘the first photo at the top of the page’ was meant to reference back to the first photo at the top of the first Flickr page, the link to which is at the bottom of post #1 above. Sorry for any confusion.

Clint M.

November 7, 2015

Offline

OfflineAny progress on your mystery, Clint?

Mike

1 Guest(s)

Log In

Log In Members

Members Home

Home

Add Reply

Add Reply Add Topic

Add Topic