May 8, 2014

Offline

OfflineHow precise were the barrels of 1885 rifles made. Considering the technology of the times, was there much variation in the finished bores from gun to gun ? Were there standards specified for the amount of variation allowed ? I am interested specifically in a high wall, # 1 barrel, 28″, .32 WCF, made in 1889. I’m mostly looking for basic information to compare with after the barrel is slugged.

Thank you.

July 17, 2012

Offline

OfflineInteresting question and one I am not equipped to fully answer since I am a rim fire guy. Many of the drawings I have seen of Winchester barrels direct the rifling, chambering dimensions and tolerances back to the Winchester “Cartridge and Chamber Book” which I have never found. I think that keeping the chamber and rifling details separate from the shop drawings probably helped create an additional layer of security for Winchester. Unfortunately I have yet to find it or a copy.

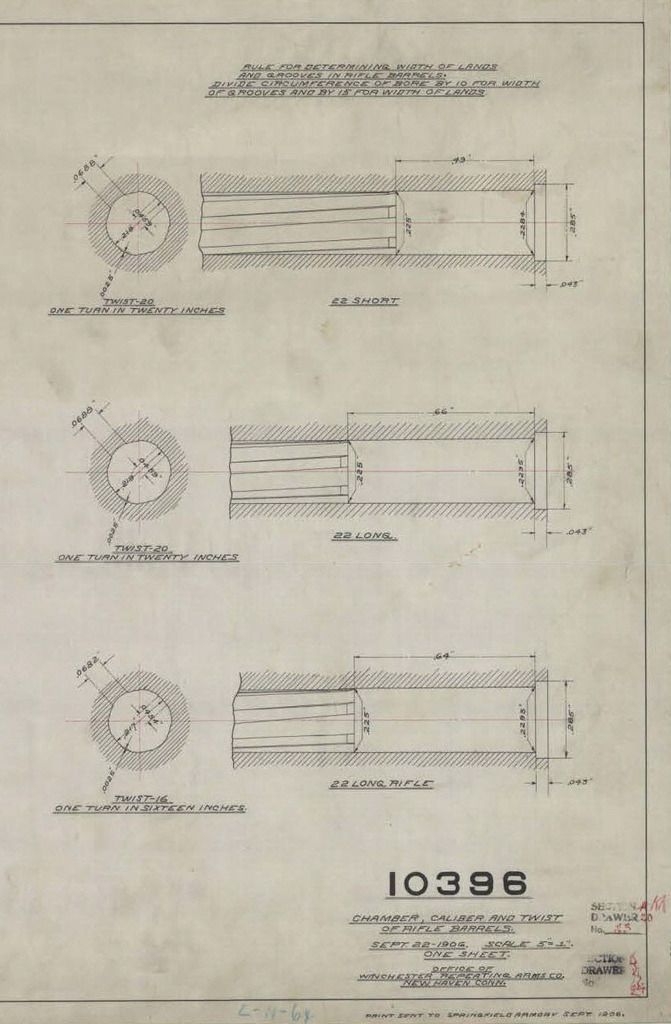

Prior to the C’tge and Chamber book some of the information was placed on the actual barrel drawings but usually not the +/- tolerances. Here is an example;

As you will note at the top of the drawing, the Winchester “rule” for determining width of the lands and grooves in rifle barrels was to divide the circumference of the bore by 10 for width of grooves and by 15 for width of lands but no +/- tolerance is indicated.

I checked some of the 1895 barrel drawings I have and could not find a bore tolerance on them but I did find a bore tolerance on the .30 caliber (.288″ bore diameter) 1894 barrel drawing of +.002″ / -.000″.

Sorry I couldn’t be more help on your question. Hopefully someone has some additional information to share.

Regards,

WACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

April 15, 2005

Online

OnlineMy observation only, there was nearly undetectable difference from one barrel to the next within the same cartridge chambering. Winchester was extremely good at producing high quality barrels that shot very accurately.

Bert

WACA Historian & Board of Director Member #6571L

April 23, 2012

Offline

OfflineBert H. said

My observation only, there was nearly undetectable difference from one barrel to the next within the same cartridge chambering. Winchester was extremely good at producing high quality barrels that shot very accurately.

Bert

Agree , and wonder why there was a noticeable accuracy detriment in the wider tolerance bore variation in Mod 1892 44-40 and 1894 38-55 making it frustrating for me to reload for accuracy (only exceptions I have come across using several of each gun)

Phil

September 19, 2014

Online

OnlineFolks,

I am not a barrel maker nor engineer, and if someone has better or more detailed information, they should jump in here. As I understand it from current production barrels of all kinds, the alloy makes a difference on how easy or hard it is to rifle the barrel and maintain very tight tolerances, especially of the groove diameter. Early Winchesters (such as the 1876’s) had relatively “soft” barrel material and were easily bored and rifled to very consistent dimensions. The 1876’s have a reputation of being very consistent as result, over their relatively short manufacturing life. Now, the model 1873 in the 44 WCF seemed to vary over its very long life as to groove diameters, but that may have been also due to changing engineering as well as materials? With the 1894 and the 1895 models, the barrel material changed between several alloys. When the stainless steel was attempted, it raised all sorts of issues as it was relatively hard, and thus there was a high rejection rate supposedly. This did not even take into consideration the ability (or lack thereof) to color the stainless barrels. At least some of this also may have applied to the 1886. I can only assume, with all the pratfalls associated with that term, it would potentially apply to the 1885 were its barrels made of varying alloys, but have to default to Bert as his experience with the 1885 would tend to indicate not a problem with them.

Where are the metallurgists, restorers and barrel folks? Am I off base here, or hitting on some of the issues? I do know in particular of seemingly wide variation in groove diameters for the .38-55 chambered 1894, and the .405 chambered 1895 (wide being a relative term). Also from an extreme of .431 groove diameter of a very nice condition, second model deluxe 1873 to a more tight .428 in a later third model with near pristine bore.

Then there arises the question in my mind, if a groove diameter of .413 is “normal” in the .405 cartridge, why are all the jacketed bullets currently available only .411 diameter? Groove diameters can go up from the .413 by a thousandths or two. It is all part of the “fun” in getting them to shoot, and shoot they can!

Tim

1 Guest(s)

Log In

Log In