July 17, 2012

Offline

OfflineYou covered all of the initial bases and proper techniques. When that fails I use a sight pusher.

Best Regards,

WACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

February 2, 2013

Offline

OfflineBig Mac said

I’m having trouble removing a barrel rear sight dovetail blank from a model 43. I coated with Kroil, let it set, and wacked a few times, L to R, with brass drift but it hasn’t budged. Any recommendations?Big Mac

I’m sure I’ll catch a lot of flack for this but here goes. Not sure where or why the L to R dovetail originated and don’t understand why the dovetail would be tapered either. That being said, I was told over 60 years ago to always remove from R to L. This seemed to have always worked for me at any rate and I removed my share of sights from firearms. If removed in the opposite or wrong direction you’ll be going into new surface area territory making it more difficult to remove. Can’t see any harm at this point for you to try removing from R-L with a brass punch or rod and see if it moves at all.

Regards, Len

July 17, 2012

Offline

Offline66m20e said

I’m sure I’ll catch a lot of flack for this but here goes. Not sure where or why the L to R dovetail originated and don’t understand why the dovetail would be tapered either. That being said, I was told over 60 years ago to always remove from R to L. This seemed to have always worked for me at any rate and I removed my share of sights from firearms. If removed in the opposite or wrong direction you’ll be going into new surface area territory making it more difficult to remove. Can’t see any harm at this point for you to try removing from R-L with a brass punch or rod and see if it moves at all.

Regards, Len

No flack from me, BUT…..The left to right removal originated from Winchester and the sight dovetail is in fact tapered and wider on the right side. The Winchester instructions, as well as most of the barrel drawings I have, indicate a right to left taper of 0⁰30′. If you drive the sight all the way through the dovetail from the right side it will enlarge/damage it.

That information pertains specifically to Winchester rifles, other manufacturers may be different. But again, DO NOT drive it out from right to left.

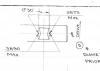

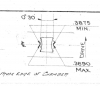

Here are excerpts from a Winchester barrel drawing which illustrates the taper and a directional arrow for installation (which is opposite the removal direction).

FRONT DOVETAIL SPECIFICATIONS (from Winchester) –

REAR DOVETAIL SPECIFICATIONS (from Winchester) –

Best Regards,

WACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

March 12, 2008

Offline

OfflineThe one “key” item that I have found is making sure you have the barrel held rigidly, and as close to the dovetail as possible to prevent any flexing of the barrel when tapping drift punch. I use a 6″ vise with leather padded jaws and position the dovetail so that the driving force is straight down. I always use a drift made of either brass or copper and make sure it has a square face to make sure all force is directed to the sight base and prevent it walking off and hitting barrel. Also, I use a relatively heavy hammer, probably 3#. One good hit usually does the job. This has always worked for me. Most damage results from not holding the barrel rigid. I always remove the barreled action from stock so I can get the dovetail as close to vise jaws as possible.

Steve

October 4, 2017

Offline

Offlineseewin said

The one “key” item that I have found is making sure you have the barrel held rigidly, and as close to the dovetail as possible to prevent any flexing of the barrel when tapping drift punch. I use a 6″ vise with leather padded jaws and position the dovetail so that the driving force is straight down. I always use a drift made of either brass or copper and make sure it has a square face to make sure all force is directed to the sight base and prevent it walking off and hitting barrel. Also, I use a relatively heavy hammer, probably 3#. One good hit usually does the job. This has always worked for me. Most damage results from not holding the barrel rigid. I always remove the barreled action from stock so I can get the dovetail as close to vise jaws as possible.Steve

I have had good luck doing almost exactly what Steve said.

I use lead vice jaws with wood removed from the gun and a big deadblow hammers not mallets.

Had an old gunsmith tell me “Don’t force it. Use a bigger hammer.”

I am curious and to what sight pushers you guys have used on rear sights. I would really like to see what you use.

Dominic

February 2, 2013

Offline

OfflineJWA said

66m20e said

I’m sure I’ll catch a lot of flack for this but here goes. Not sure where or why the L to R dovetail originated and don’t understand why the dovetail would be tapered either. That being said, I was told over 60 years ago to always remove from R to L. This seemed to have always worked for me at any rate and I removed my share of sights from firearms. If removed in the opposite or wrong direction you’ll be going into new surface area territory making it more difficult to remove. Can’t see any harm at this point for you to try removing from R-L with a brass punch or rod and see if it moves at all.

Regards, Len

No flack from me, BUT…..The left to right removal originated from Winchester and the sight dovetail is in fact tapered and wider on the right side. The Winchester instructions, as well as most of the barrel drawings I have, indicate a right to left taper of 0⁰30′. If you drive the sight all the way through the dovetail from the right side it will enlarge/damage it.

That information pertains specifically to Winchester rifles, other manufacturers may be different. But again, DO NOT drive it out from right to left.

Here are excerpts from a Winchester barrel drawing which illustrates the taper and a directional arrow for installation (which is opposite the removal direction).

FRONT DOVETAIL SPECIFICATIONS (from Winchester) –

REAR DOVETAIL SPECIFICATIONS (from Winchester) –

Best Regards,

Whooops……… In my mind I’m looking at the barrel from the muzzle end as this is how I always ended up removing/adjusting my front sights…….. Thanks for taking the time and getting me star

JWA said

66m20e said

I’m sure I’ll catch a lot of flack for this but here goes. Not sure where or why the L to R dovetail originated and don’t understand why the dovetail would be tapered either. That being said, I was told over 60 years ago to always remove from R to L. This seemed to have always worked for me at any rate and I removed my share of sights from firearms. If removed in the opposite or wrong direction you’ll be going into new surface area territory making it more difficult to remove. Can’t see any harm at this point for you to try removing from R-L with a brass punch or rod and see if it moves at all.

Regards, Len

No flack from me, BUT…..The left to right removal originated from Winchester and the sight dovetail is in fact tapered and wider on the right side. The Winchester instructions, as well as most of the barrel drawings I have, indicate a right to left taper of 0⁰30′. If you drive the sight all the way through the dovetail from the right side it will enlarge/damage it.

That information pertains specifically to Winchester rifles, other manufacturers may be different. But again, DO NOT drive it out from right to left.

Here are excerpts from a Winchester barrel drawing which illustrates the taper and a directional arrow for installation (which is opposite the removal direction).

FRONT DOVETAIL SPECIFICATIONS (from Winchester) –

REAR DOVETAIL SPECIFICATIONS (from Winchester) –

Best Regards,

Whooops……… In my mind I was looking at the barrel from the muzzle end because that’s how I always end up moving or adjusting my front sights and should have stated same. I do apologize for my stupidity on this issue and very glad you posted excerpts before anything got ruined. Best……

March 31, 2009

Offline

OfflineOldgrayguns said

I have had good luck doing almost exactly what Steve said.

I use lead vice jaws with wood removed from the gun and a big deadblow hammers not mallets.

Had an old gunsmith tell me “Don’t force it. Use a bigger hammer.”

I am curious and to what sight pushers you guys have used on rear sights. I would really like to see what you use.

Dominic

I too would like to see a picture of a sight pusher. I have been trying to remove the rear sight on my 66. Just been flattening the end of the brass punch. Used many products including Kroil and let them all soak for weeks. I am using a big brass hammer too. Someone said the sight may be silver soldered? The sight has movement up and down at both ends but nothing side to side. I have not tried heat. I am afraid to use a small torch. I am not concerned for the sight since I will replace it with the correct sight. The sight that is on it now is a common period replacement.

September 7, 2017

Offline

OfflineThanks to all for the responses and advice. I tried again this morning before I had read all the responses. Suffice to say no luck even with another overnight in Kroil. I locked the rifle back up for today so it has time for me to cool down. My next attempt will be per Steve’s directions. I’ve got the vice and round face brass drift, will check with Brownell’s for a square one.

Big Mac

July 17, 2012

Offline

OfflineBrownells sells a triangular brass punch in several sizes specifically for sights in dovetails. That is what I use but I like Steve’s 182 idea.

WACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

March 12, 2008

Offline

OfflineI have always found the store bought brass drift punches way too soft for my liking. I think you can get small quantities of 182 from On-Line metals, or McMaster Carr. I also like 954 aluminum bronze, again much harder and more durable than copper or brass. I prefer to make my own drifts, and think you will find you can make a much better product and less cost than anything you can buy if you are so inclined.

Steve

I knocked the back sight out of my new Model 70, 375 H&H Alaska and found that the sight has a slight taper on the left side of the dovetail, you can see it when in the light just so. This tells me the sight goes in RIGHT to LEFT from the factory. Removal should be LEFT to RIGHT.

March 31, 2009

Offline

OfflineI’ve tried every method described and I still can not get the rear sight to budge on my 66. Believe me I have used many products, soaked for many weeks, heat, steel punches and big hammers. If someone has a sight pusher that works on our octagon barreled guns please post a picture or a web sight where I could purchase or make one. My sight appears to be very tight in the middle but the ends seem loose. I don’t want to cut and destroy the existing sight but I may have to do that. The sight on the gun is a period/factory replacement that you see on Henry’s and 66’s instead of the ladder sight. Although this is not an expensive sight it is rare.

Log In

Log In