February 27, 2021

Offline

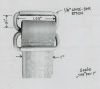

OfflineI have purchased some original hooks. It looks like the leather sling width was 1-1/8″ or 1-1/4″. What is the correct width, so that I can order some leather strap material?

I have photographs of an original sling assembly on a M1894 from some member here.

I also wanted to ask if one end of this sling was riveted or laced, as my pics do not show that detail.

July 17, 2012

Offline

OfflineWACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

July 17, 2012

Offline

Offlinevictorio1sw said

Does anyone sell those roller-link adjusters?

Not that I know of. There are also various versions of that model sling, depending upon the vintage of your Model 1894. The earlier buckle sleeves were marked with the patent date, later sleeves were unmarked. Your 1898 rifle would have had patent-marked sleeves.

Best Regards,

WACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

These slings are 1″ wide. The slide appears to have rollers on it, but they are actually sleaves that fit over the wire loop and do not turn or roll. The patent date is 1897, but I’ve never found out who might have made them. Who ever was making these slings, was buying this hardware from either the manufacturer or a wholesale warehouse. I’ve used thousands of pieces of leather hardware in my business for years and have dozens of wholesale/retail saddlery hardware catalogs. I’m on a continuous search for these slides, but have not found anything like this. These are a true unicorn. There are similar items available, but they aren’t close enough that I would want to start reproducing this sling. In the past, I have been in contact with hardware manufactures to check the possibility of having an old item reproduced. Most manufacturers have wanted a minimum order of at least 2000 pieces and as high as 10,000. Kinda takes the fun out of reproducing these slings.

July 17, 2012

Offline

Offlinewin4575 said

These slings are 1″ wide. The slide appears to have rollers on it, but they are actually sleaves that fit over the wire loop and do not turn or roll. The patent date is 1897, but I’ve never found out who might have made them. Who ever was making these slings, was buying this hardware from either the manufacturer or a wholesale warehouse. I’ve used thousands of pieces of leather hardware in my business for years and have dozens of wholesale/retail saddlery hardware catalogs. I’m on a continuous search for these slides, but have not found anything like this. These are a true unicorn. There are similar items available, but they aren’t close enough that I would want to start reproducing this sling. In the past, I have been in contact with hardware manufactures to check the possibility of having an old item reproduced. Most manufacturers have wanted a minimum order of at least 2000 pieces and as high as 10,000. Kinda takes the fun out of reproducing these slings.

The buckle system was invented by W.O. Perkins and Winchester’s T.C. Johnson. The subsequent patent was assigned to Winchester which is why you will not find them in a hardware catalog.

Here is the patent the buckle date references for your records. You will also notice that T.C. Johnson invented the quick release sling swivel which we still use today……

Best Regards,

WACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

July 17, 2012

Offline

Offlinevictorio1sw said

Well, now we see why the “roller” sleeve existed on this device – to hide the joint. This part just got much harder to make too!

Yup. I was trying to figure out how they neatly bent the wire ends into the sleeve also. Let me know if you figure it out

Best Regards,

WACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

February 17, 2022

Offline

OfflineJWA said

victorio1sw said

Well, now we see why the “roller” sleeve existed on this device – to hide the joint. This part just got much harder to make too!

Yup. I was trying to figure out how they neatly bent the wire ends into the sleeve also. Let me know if you figure it out

Best Regards,

I have been looking for a couple of these for quite sometime, to no avail. I have sat and stared at the one I do have and until Jeff posted those pictures ,I for the life of me could not see how the ends were stuffed into the sleeve, but I think I got it now. As soon as the weather here gets better and i can get out with out freezing I will try my idea and report back on this. But as far as I can see it looks like it was 7 step prosses.

July 16, 2013

Offline

Offlinevictorio1sw said

I have no idea. A manufacturing marvel, I guess! 🎈🎈🎈Unless that “roller” sleeve was the last stage of manufacture, and was bent around those two joined ends.

That would leave the sleeve with a longitudinal seam.

From an engineering point, if I was making it the sleeve would have enough lateral movement to cover the joint which would be just inside the bend on one end, so when the sleeve is slipped on and the inner pushed back into the but point the sleeve would cover the joint

Log In

Log In

Online

Online