January 26, 2011

Offline

OfflineNovember 7, 1987

Offline

OfflineThis is interesting

A few of mine

26″ 1/2 O 30WCF .658

26″ 1/2 O 38-55 .658

26″ R 30WCF .696

26″ O 30WCF .708

24″ O 30WCF .714

extra lites

26″ R 30WCF .482 I think this is the smallest 1894 barrel Winchester made

26″ O 32-40 .578

22″ 1/2O 38-55 .575 Never measured many before seems like a lot of variations

April 30, 2006

Offline

OfflineBarrel (muzzle) diameters vary so greatly that it is very hard to put an absolute specification on them. Think of lengths, calibers , configurations, etc., etc., and safety regarding the thickness of the barrel material at the muzzle in relation to the caliber’s groove diameter. Then think of aesthetics involving tapers when using the barrel/receiver diameter as a more-or-less absolute.

That is why I don’t pinpoint any of these specs in any of my writings. I did however, submit a guide to recognizing a cut-off barrel regarding trappers and short rifles, sometime back, in “The Winchester Collector.”

Cheers,

Bob

January 24, 2013

Offline

OfflineActually, the deviation in muzzle size is not all that great, well within manufacturing tolerances, that’s If you group the barrels by shape (OCT, Round etc.) and do an apple to apple comparison.

Looking at the octagon barrels, if you extend all the lengths out to 26 inches, using Winchester’s standard taper of .005 per inch you will see that they will range from .700-.714 with an average size of .706

So if we use .706 as the norm, we look at the two extremes: .700 and .714. The one with the smaller barrel is .006 off the statistical norm. That equates to .003 per side, the average thickness of a human hair is .003, so in reality it’s a hair per side smaller than the norm.

The larger barrel is .714 or .008 larger than the statistical norm, at .004 per side that equates to one and 1/3 hairs per side.

Gentlemen, we are truly splitting hairs.

If you look at the standard round barrels, bring the three examples given out to 26 inches, you will find that they are identical +/- .000

The key piece for large manufacturing is interchangeability. It would not make sense for Winchester to deviate too much from the standard barrel dimensions, otherwise the forened wood and forend caps would not fit correctly, and Winchester certainly did not want to custom make forend caps and wood for each barrel.

Winchester also used the standard forend caps for short rifles with short forends

V/R

Mike

July 17, 2012

Offline

OfflineWACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

January 24, 2013

Offline

OfflineJWA

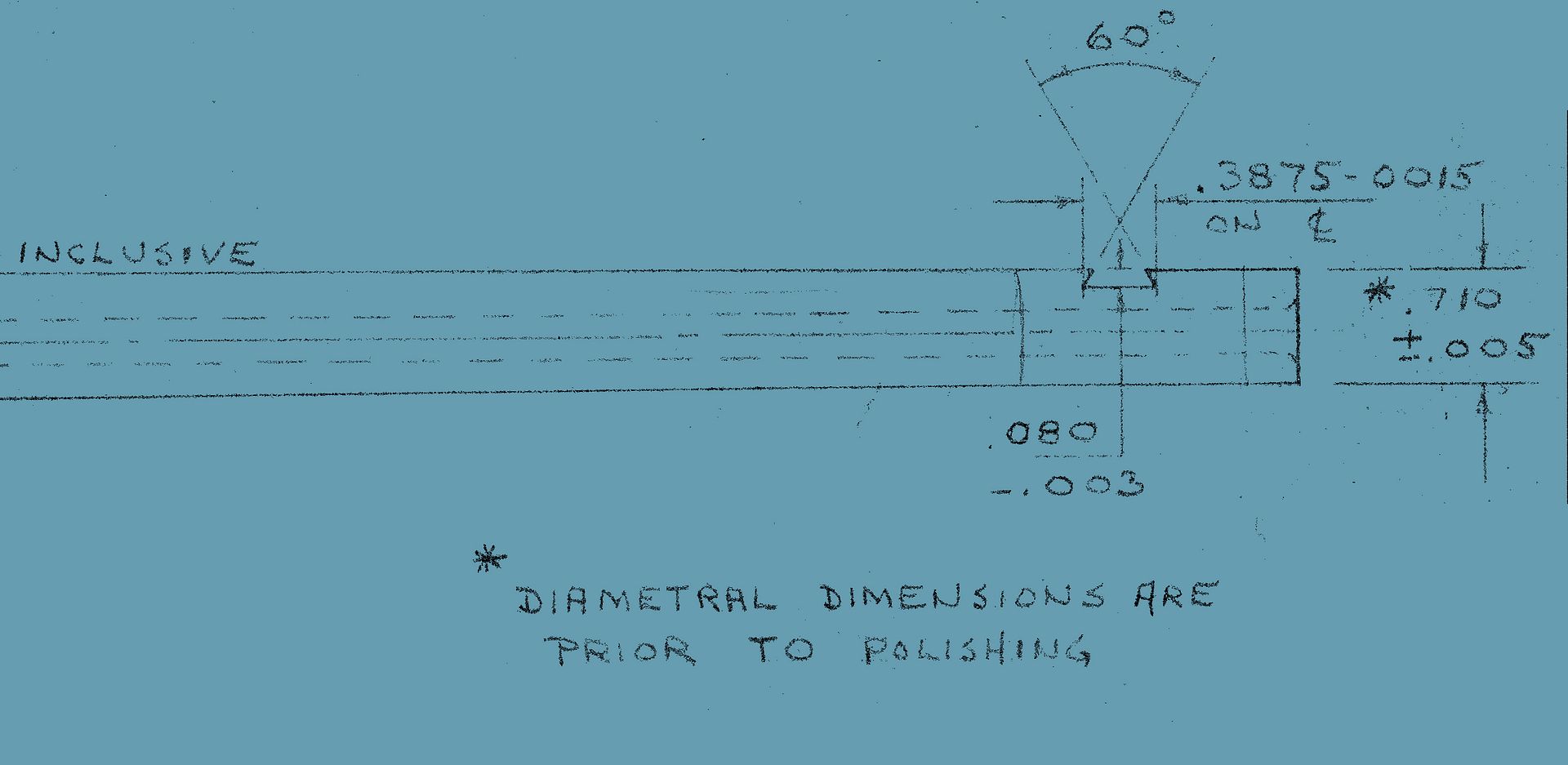

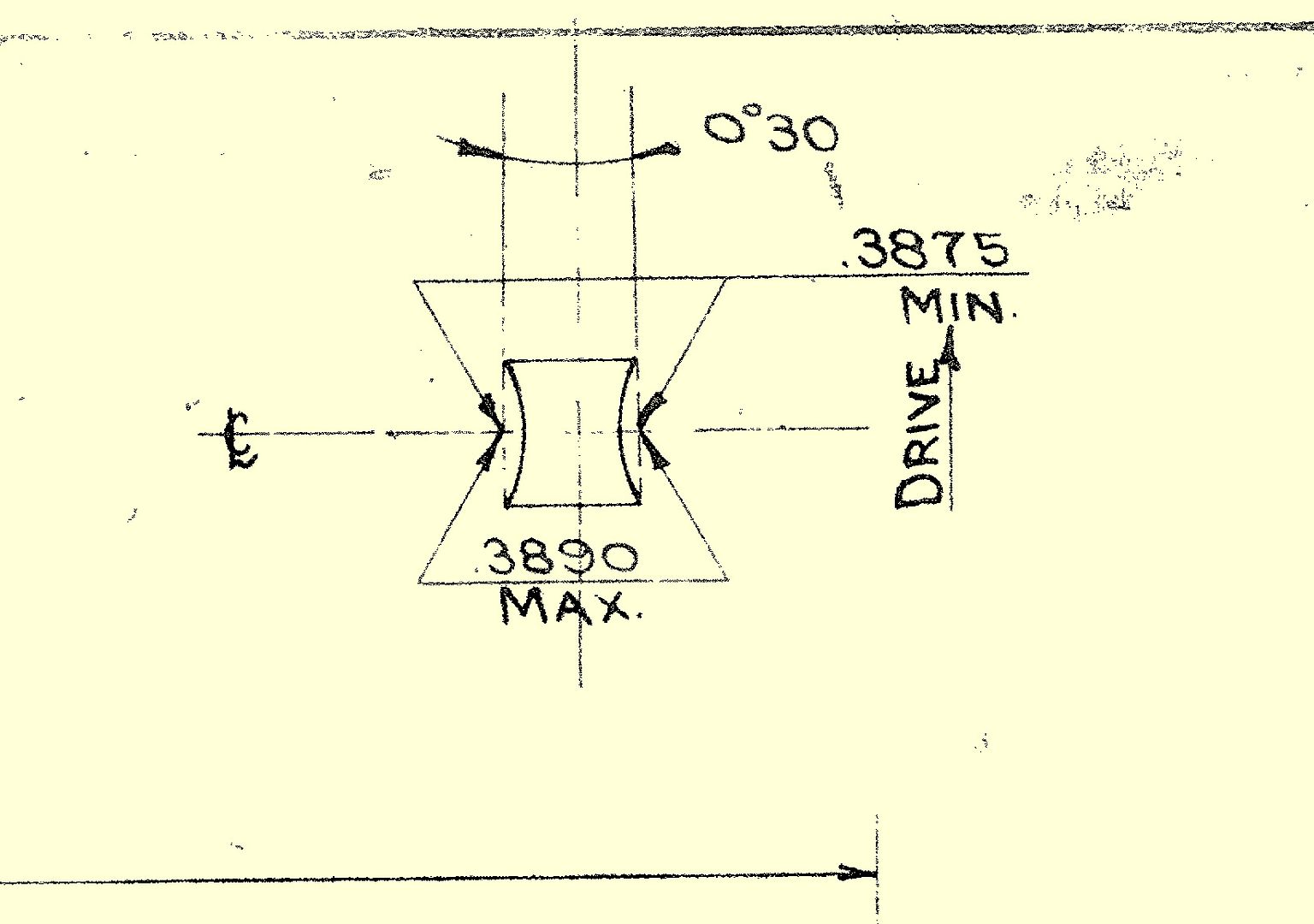

Interesting drawing, would like to find out more about it.

Interesting size on the front sight DT, does not equate to any fractional size.

For the OP, if .710 +/- .005 is indeed the correct factory measuments, then your barrel is out of spec and you must dispose of it immediately, I’m sorry Sir, those are the rules.

V/R

Mike

July 17, 2012

Offline

OfflineHi Mike,

That barrel drawing is for a different Winchester model which I had handy, I just posted the excerpt to illustrate the dimensional tolerance of +/- .005″ which was pretty standard on a lot of the models and the note about the muzzle diameter measured pre-polishing which could have some impact on the final O.D.

Good catch on the front sight dovetail, we have always refered to it as a 3/8″ dovetail but apparently it is a skosh larger

Now you have me curious and I will check a few more Winchester barrel drawings tonight to see how the front dovetail is dimensioned.

Best Regards,

.

WACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

July 17, 2012

Offline

OfflineWACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

July 17, 2012

Offline

OfflineHi Mike,

I just responded to your PM which I didn’t notice until after I had posted…..sorry.

Regards,

WACA Life Member #6284 - Specializing in Pre-64 Winchester .22 Rimfire

March 19, 2014

Offline

OfflineJWA said

Excellent post Mike! You must be a fellow Engineer

Also, according to some of the Winchester barrel drawings, not only was the machining tolerance +/- .005″, the diametral dimensions were prior to polishing.

Best Regards,

.

Good post. When you are talking about decimal dimensions many don’t realize how small .005 in. is. When you are talking outside barrel dimensions it makes absolutely no difference and holding finer tolerances where they don’t matter slows production for no reason. I’m a machinist by trade and generally speaking, the finer the tolerances demanded, the more expensive the work is. General rule of thumb with drawings dimensioned to three decimal places and a tolerance not given is + or – .005 in.

January 24, 2013

Offline

OfflineFrom the data presented here, and from the barrels that I have measured over the years, I suspect that Winchester used standard barrels for their short rifles. My guess is that if a short barrel was needed, a workman would get an already machined octagon or round barrel blank, shorten it to length and machine the appropriate dovetail cuts. The fact that Winchester didn’t make special forend caps for short forend rifles, supports this hypothesis. Conversely, Winchester did make special forend bands for the carbines with shorter wood, as the taper was too great for the standard band.

Also what is interesting are the specs for the dovetail cut, at .3875 it’s .012 larger than the standard 3/8; large enough that another manufacturer’s sight would be fairly loose in the dovetail.

1 Guest(s)

Log In

Log In