June 15, 2024

Offline

OfflineBert,

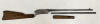

In case you don’t already have it in your survey, I recently picked up s/n: 833,707. It is carbine, chambered in .30 WCF, has a 20” round barrel and full length magazine tube, and a has smooth and plain walnut stock fitted with the carbine style crescent butt plate.

I believe the serial number places this guy in 1916 with my guess of a June date of manufacture.

Aside from the rear site, everything else appears to be original to the gun. Unfortunately, the upper tang is fractured so I will need to get it welded.

FWIW, the stock has a “25” carved or stamped in it and the bottom of the barrel is marked “MNS” which I believe indicates Midvale Steel Company made the barrel.

November 7, 2015

Offline

OfflineAlaska94 said

Yeah, I like cleaning them up. This was advertised and priced as a project gun, so I’m off on my next journey.

Apparently you like a challenge. I admire your courage and ambition!

Mike

June 15, 2024

Offline

OfflineThanks Bert! I always appreciate your input and counsel. I will definitely post pics as I work on this one. I thought the stock wood looked off for walnut, so thanks for clarifying that they are gumwood.

I’m planning to work on the scratches on the receiver. Given there are scratches on both sides of the receiver and in similar locations and patterns, I’m speculating they are from some sort of case or holster this was repeatedly slid in and out of. Anyway, I expect I will end up taking the remainder of the bluing off. Just throwing that out there welcoming opinions before I commit a cardinal sin. As we all have noted, this one is in rough shape, so I’m not sure I’m doing any real harm to it.

April 15, 2005

Offline

OfflineAlaska94 said

Thanks Bert! I always appreciate your input and counsel. I will definitely post pics as I work on this one. I thought the stock wood looked off for walnut, so thanks for clarifying that they are gumwood.I’m planning to work on the scratches on the receiver. Given there are scratches on both sides of the receiver and in similar locations and patterns, I’m speculating they are from some sort of case or holster this was repeatedly slid in and out of. Anyway, I expect I will end up taking the remainder of the bluing off. Just throwing that out there welcoming opinions before I commit a cardinal sin. As we all have noted, this one is in rough shape, so I’m not sure I’m doing any real harm to it.

Nothing you can do to it now is going to negatively affect or harm it… the damage has already been done.

Bert

WACA Historian & Board of Director Member #6571L

June 15, 2024

Offline

OfflineSome progress pictures. Things are cleaning up nicely. I need to schedule the weld for the upper tang and then finish work on the stock and forearm. Aside from how she looked on the outside, this one was seemingly well cared for on the inside. Everything disassembled very easily and the parts were not overly grimy. The bore cleaned up quickly and appears to be in really good shape.

August 27, 2014

Offline

OfflineThose are ‘forging striations’ not scratches on both sides of the receiver. They are a normal part of the manufacturing process on M1894’s of this era. Those who know what they are like to see them on a gun

“If you can’t convince them, confuse them”

President Harry S. Truman

June 15, 2024

Offline

OfflineTedk said

Those are ‘forging striations’ not scratches on both sides of the receiver. They are a normal part of the manufacturing process on M1894’s of this era. Those who know what they are like to see them on a gun

Thanks Ted. I had a feeling the horizontals were something from manufacturing as I had read something about them somewhere. Didn’t know what they were called. I appreciate you sharing. When I clean these up I document them, so now I know what to refer to them as.

December 9, 2002

Offline

OfflineI’m in agreement with Ted, on the receiver striations.

I’m curious to know how you plan on tackling the broken top tang, in regards to welding and repairing the broken tang, and trying to preserve the “Winchester Roll mark”! I’m guessing that it’s far enough, away from the Roll Mark, that if you keep you’re heat low enough, and tackle the job properly, you can accomplish this feat!

Interesting project, all in all! Not for many of the true die hard collectors, but it’s not meant to be either!

Good Luck, thanks for sharing!

Anthony

June 15, 2024

Offline

OfflineAbout 4 months after dropping this guy off for the weld job it was finally ready for pickup yesterday. I am pretty happy with how it turned out. Unfortunately, a few other issues were identified:

With the action closed, the carrier is not fully lowering, which obstructs the loading gate. The problem seems to be with the carrier and not the carrier spring. I sanded the portion of the carrier that meets the spring when in the lowered position and reseated the loading gate. This seems to have corrected things but more testing is needed. Any suggestions for other fixes are welcomed.

With the action open, the trigger was sliding past the stop, essentially rendering the safety worthless. I was able to isolate the issue to the trigger. Just enough wear in the area that meets the trigger stop to allow it to slide right by. A replacement trigger is on order.

The worst news was excessive headspace. I’ve ordered an oversized locking block to hopefully address this and get this guy functioning as a shooter.

Next up for me is refinishing the Gumwood stocks. I plan to hand rub them with BLO. I’ve done this successfully with Walnut stocks but have no experience with Gumwood. Any tips are welcome.

June 15, 2024

Offline

OfflineSome updates…

Replacing the trigger fixed the issue with the safety not functioning properly.

I’m chalking the carrier/loading gate issue up to not perfect but also not a major mechanical problem. Slightly opening the lever allows a round to be fed through the loading gate. Once the first round is in the magazine the action can be locked up and the loading gate functions normally.

I picked up some Forster headspace gauges and confirmed the headspace diagnosis. The action fully closed over the Go, No Go, and Field.

I replaced the locking bolt with a 0.010 oversized one I had. Now the action closes ~98% of the way over the Go gauge, does not close at all over the No Go, and if I gently work the lever the extractor will try to bite over the Field gauge but the action will not close.

With a factory round in the chamber the action will close up tight and extract/eject the round when cycled.

Next step will be a test fire to confirm, but I feel like the headspace issue has been solved.

The fourth coat of BLO went on the wood yesterday and it’s starting to look good. I’m planning on 2 more coats over the next seven days for a total of six.

May 14, 2025

Offline

OfflineAlaska94 said

A few progress photos. This is after 6 coats of BLO on the wood. A few more days of drying and then I’ll burnish. A month after burnishing, I’ll apply clear beeswax. After that I’ll put it all back together.

BeforeAfter

Already looks amazing compared to what you started with! I admire what you are doing and can’t wait to see the finished product! Congrats and thanks for sharing the journey on this beauty!

June 15, 2024

Offline

OfflineThank you! I appreciate the feedback. This one has a lot of character. As a 1916 it’s WWI era and also the 50th anniversary of Winchester Arms. The rough exterior shape along with the worn trigger to me suggest this guy saw a lot of use. The broken tang along with the chips out of the stock and forearm on the left side, both near the receiver paint the picture of some significant trauma, maybe a horse roll? The 25 stamped on the arm of the stock indicate it was an inventoried item with perhaps at least 24 siblings. Maybe a security service or a ranch gun. All speculation of course but fun to imagine this carbine’s early life.

I’m planning to give this to a close friend for his birthday. He was born on the 25th, so a convenient coincidence with the stock stamp.

Log In

Log In